Post-crash inspections

Written by Chris Mulcahy RC Helicopters Column As seen in the February 2018 issue of Model Aviation.

There are no two ways about it—crashing stinks. Some of us like to dive right in and start stripping a helicopter apart, while others like to shelve the project until the aggravation from crashing has worn off. Whichever way you deal with it, we all end up having to examine the machine to see what’s broken and needs to be replaced. There are the obvious parts, of course: blades, main shaft, head spindle, etc. But are there things that we should be checking that perhaps we don’t? For instance, the main gear. At first glance it looks okay; none of the teeth are missing, and there are no signs of them rubbing on anything and being ground down. It’s worth a second look though.

A not-so-obvious place to check for damage after a crash is the bolt holes in the main gear. Stress lines can lead to cracks.

How about where the main gear bolts onto the autorotation hub? Are there any stress marks snaking out from the bolt holes that could later develop into cracks? Did you check both sides of the gear? Chances are that if there are no signs of damage on the teeth, the gear is okay, but it is worth a second look. Stress marks will lead to cracks, which could result in a gear exploding in flight. If you’re lucky, you might discover the cracks on the ground (ask me how I know!). What about the tailboom? It looks straight, but it is worth pulling out of the helicopter to check because sometimes a small bend is hard to detect if it creases right at the tailboom clamps. Although a slightly bent tailboom might not seem like much of a problem, your gyro might notice, and it could put more strain on your torque tube than necessary. Bearings always look okay, but are they? It is easy enough to check a bearing, but it is easier to check them if you pull them out. Hold the bearing and put a little pressure on the inner race as you turn it. If it is smooth, you are good to go. If it feels notchy, it’s time for new bearings.

An easy way to check bearings is to push down on the inner race and rotate it. It should be smooth. If it is notchy, it is time to replace it.

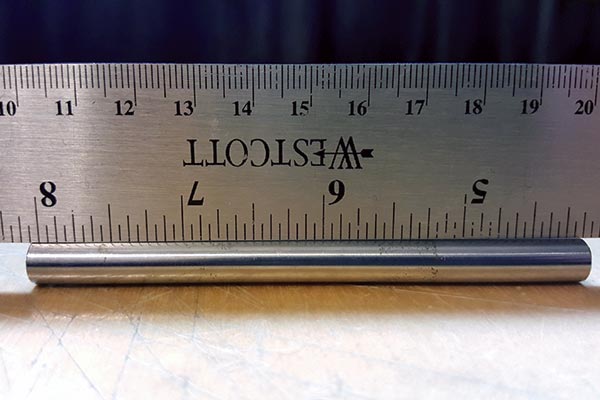

Main shafts, head spindles, and tail shafts can be tricky too. To the naked eye, they might appear straight. These parts, more than any other, will cause problems if they are slightly bent, even though they might look straight. If in doubt, replace the part. If you have a flat glass surface or a mirror, you can roll the shaft on it and check for gaps as it rolls. Servos can be damaged and have no visual clues. Usually it is gear related, which won’t become apparent until you power them up. Sometimes you can feel it if you move the servo horn by hand. It only takes one broken tooth to cause problems. Occasionally, a motor will burn out or a cable can be cut. Today’s gear trains are so robust that a servo horn will either break or bend before the gears strip in the servo, but it is good practice to check them over before flying again.

If you don’t have access to a flat piece of glass or a mirror on which to roll a main shaft or head spindle, you can use a metal straightedge to get a good idea of whether the part is bent.

For nitro-powered helicopters, the clutch liner is a good thing to check. It is possible to warp the actual clutch bell, depending on the severity of the crash. Clutch liners are easy to replace, but replacing the bell itself can be more expensive. The clutch liner is a good example of something that you can’t really check until you take it apart. If your heli is already in pieces from the repair process, it is worth spending extra time to examine the parts that are harder to get to, and might not necessarily show any signs of damage. When all is said and done and your helicopter is back together, it should fly just as well as it did before your “unplanned landing.” -Chris Mulcahy [email protected]

1 comments

Crash Inspections....

Add new comment