Stepcraft-2/420 Desktop CNC System

Written by Rachelle Haughn Several tools rolled into one Product review As seen in the January 2018 issue of Model Aviation.

Bonus Video

Have you ever purchased a short kit or ordered precut balsawood? If so, did you find yourself constantly checking your email for shipping updates or impatiently waiting for a big brown truck to pull into your driveway? You likely have thought to yourself, “I could have cut the parts quicker than they shipped.” Well, now you can! The Stepcraft-2/420 Desktop CNC System allows you to cut parts for your aircraft from the comfort of your home or workshop. It’s available in several sizes to fit modelers’ needs. Not only can it cut balsa, but with the right attachments it’s capable of cutting metals, carbon fiber, a variety of wood, and plastic. It can perform tasks such as milling, 3-D printing, engraving, laser engraving, routing, woodworking, carving, hot-wire cutting, and wood burning. It can also be used for scrapbooking.

The Stepcraft-2/420 has a small footprint and would easily fit on a desk or workbench. It is also available in smaller and larger sizes.

The Stepcraft-2/420 measures 213/4 x 171/2 inches, with a 161/2 x 11.8-inch work surface. It currently retails for $1,499, plus shipping. The other available models are the Stepcraft-1/210, which is the smallest, the 2/300, the 2/600, and the largest is the 2/840, which would be useful for woodworking, large hobby model projects, and large craft projects. The kit versions of these range in price from $999 to $1,999. All are also available in ready-to-run versions, with additional costs for assembly and shipping. The review model was sent as a kit. According to Don Sanqunetti, a volunteer at the National Model Aviation Museum, in Muncie, Indiana, who put the kit together, all of the screws and each piece came carefully and neatly packed in Styrofoam. Nothing came preassembled in the kit, which contains more than 100 parts (most are screws) and grease. A rotary tool was included with the review model, and spindles are available for an additional cost.

All of the pieces needed to build the Stepcraft come neatly and securely packaged. The Stepcraft Desktop CNC System can also be purchased prebuilt.

The first thing that Don did after opening the box was to clear off his workbench and spread the parts on a mat, as instructed in the 56-page manual. When he flipped through the full-color instruction book, he noticed that the steps were clearly laid out with diagrams. “Some people compare [these instructions] to a Lego construction set because everything is very well instructed and labeled,” Don commented. “But I’m older than that—I grew up with Erector sets in the ’50s.” The kit does not provide the tools needed to assemble the Stepcraft. These include several sizes of Allen wrenches, a slotted-head screwdriver, long-nose pliers, a cutting tool, box wrenches in four sizes, superglue, a measuring tool, and multipurpose oil. Listed with each step are the required parts for that step. There are no written, step-by-step instructions, which Don didn’t find problematic. For those who need more explanation, several helpful free videos are available on Stepcraft’s YouTube channel. Builders can also find videos for each step at www.stepcraftsupport.com/assemblycourse. According to Stepcraft’s website, the average assembly time is 6 to 8 hours, with an additional 1 or 2 hours needed for final adjustments. Don, who has been building model aircraft kits for most of his life and has experience with CNC machining, said he worked on the project for roughly 16 hours over the course of four days. He added that the kit was fun to build. During the build, Don had one point of confusion. He found that a drawing of the end switch bracket didn’t match up with the actual part sent with the kit, but later noticed that there was a note next to the drawing stating that the part shape had changed.

UCCNC software is included with every Stepcraft CNC machine.

After the machine was put together, it was time for Don to start cutting. The Stepcraft-2/420 comes with the UCCNC software to control the machine. The software comes on a disk and uses a G-code to communicate with the printer. If you lose or break the disk, the software can be downloaded from the company’s website. If you purchase a Stepcraft in the US, Canada, or Mexico, it comes with a card for a free year of Autodesk Fusion 360 CAD/CAM software. Also included is a parallel-to-USB interface for the Stepcraft, which allows you to connect it to a computer via a USB cable. The included cable must be plugged in for the Stepcraft to function. All commands to the Stepcraft are made by clicking on an icon in the computer software. The machine has no buttons, except for an emergency stop knob.

The Stepcraft is entirely controlled by computer software that comes with it. This emergency stop knob is the only control that is on the machine.

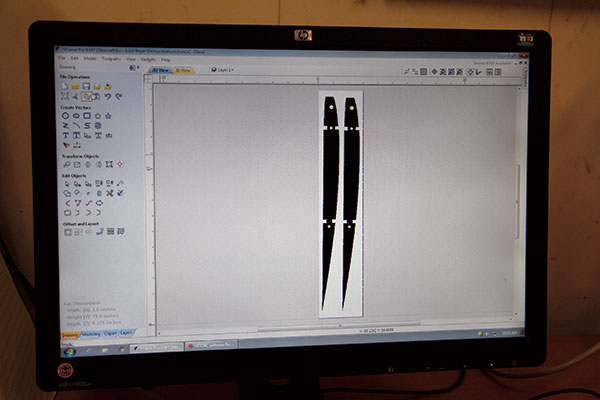

AMA was provided a copy of VCarve V9 Pro software, which retails for $699 on the Vectric website, to use with the review model. Don used it to cut out balsa wing ribs. When the machine cut out the ribs, it left small tabs on each side that needed to be cut with a hobby knife to free the parts from the material.

Before they were cut, the wing ribs were scanned into VCarve Pro. Design software to use with the Stepcraft-2/420 Desktop CNC System is available separately.

“It did what we wanted it to do,” said Greg Prater, AMA Plans Service coordinator, who helped Don operate the machine. “It works better as a router than I thought it would.” “It takes a while to learn [how to use it],” Don added. “I would give it a fairly steep learning curve, but it’s doable,” Greg stated. When using the machine, the included cross clamps with bolts fit into slots in the frame to secure wood and other materials and prevent them from shifting during cutting. The bolts can easily be adjusted to secure materials up to 1/2 inch thick. The cutting area is a white Formica hardboard table and Stepcraft suggests that you put some type of waste board under the material that you are cutting to prevent damaging the Formica. The Stepcraft can cut at a maximum speed of 50mm per second/107 inches per minute. If you choose to purchase the 3-D printing option, it can print objects at a maximum height of 4.72 inches.

In addition to a variety of wood, the machine can quickly cut though many types of materials, including metal, carbon fiber, and plastic.

If you wish to cut more than basic wood, there are four optional packages available that range from $1,799 to $4,499. Several accessories, tools, and bits are available through the Stepcraft website for an additional cost, giving Stepcraft Desktop CNC System owners endless options for projects. The attachments can quickly and easily be interchanged. Don said that one of the options he would like to have is a dust collection system and that it would be nice to have the ability to make signs, plaques, and the AMA emblem. The museum plans to use the Stepcraft for restoration projects and to create replicas of model aircraft that are no longer in existence, Greg said.

These wing ribs, cut by the Stepcraft, will be used to build a 1/2-scale de Havilland D.H.2.

“It will open some doors for us in terms of cutting formers, wing ribs, etc., as we look at building reproductions of historic aircraft or building exhibits. More tools means increased capabilities,” said Michael Smith, who is the National Model Aviation Museum director. “It will be a wonderful asset to the museum’s [workshop].” If you are ready to get building sooner rather than later, consider giving the Stepcraft Desktop CNC System a try. —Rachelle Haughn [email protected]

Add new comment