Precision Aerobatics XR-61 ARF

Written by Mike Hurley A well-designed and capable aerobat Product review Photos by the author As seen in the June 2016 issue of Model Aviation.

Specifications

• Model type: Electric sport flier/3-D aerobatic ARF • Skill level: Intermediate • Wingspan: 61 inches • Wing area: 807 square inches • Length: 57 inches • Wing loading: 12.76 ounces per square inch • Ready-to-fly weight: 4 pounds, 9 ounces • Power system: 1,000-watt brushless outrunner; 70-amp ESC • Flight duration: 5 to 7 minutes • Radio: Minimum four-channel transmitter/receiver • Construction: Built-up balsa, plywood, carbon fiber, fiberglass, and lightweight iron-on covering • Street price: $299.95; airplane with optional iPAs package: $679.95Test model details

iPAs Package • Motor: Thrust 50 brushless outrunner • ESC: Quantum 70-amp ESC with BEC • Propeller: Vox 15 x 8 wood and CNC aluminum propeller adapter • Servos: Four Hitec HS-5245MG • Servo arms: Carbon-fiber servo arm extensions for the original plastic arms • Servo wire extensions: Soldered-in lightweight wireSelected to complete

• Radio system: JR XG11 DMSS transmitter • Receiver: JR RG712BX (the RG612BX might be more appropriate) • Batteries: Two PA V3 3S 2,200 mAh LiPo packs; also tested with one 6S 2,200 LiPo pack • Connectors: Deans soldered-on connectorsOptions

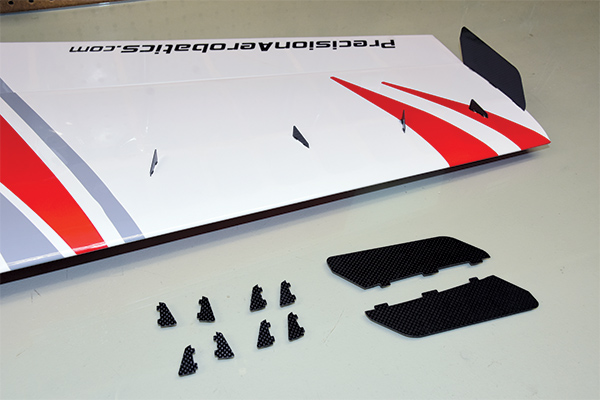

• Vortex generators: I flew the airplane with and without vortex generators and noticed little difference. The airplane might be slightly more stable in a Harrier, but I didn’t notice an increase in knife-edge performance • Carbon-fiber spinner • Wing bags: Fantastic quality; these are a must.Pluses

• State-of-the-art design and engineering. • Lightweight, ridged, carbon-reinforced construction. • Designed like a much larger airplane. • Well constructed at the factory. • No calculations for the drive systems—just build and fly. • Smooth and docile flight on low rates. • Stable with powerful control in high-alpha flight on high rates. • It’s beautiful.Minuses

• Model required sanding, filing, and fitting. • A factory-installed motor box would simplify assembly.It’s been a while since I’ve had the chance to fly anything smaller than a 30% model, but lately I’ve gotten the bug for a small airplane. I have been looking hard at available offerings. I’ve been building models for many years, and I love the design and sophistication of built-up wood aircraft. Done right, they can be so beautiful. I had already decided to try one of the products from Precision Aerobatics, so when I received the offer to review the company’s XR-61, I was thrilled. Precision Aerobatics’ designs fit my style and sense of aesthetics. The company’s aircraft are designed much like a Giant Scale aerobatic airplane with slightly more delicate construction and more attention to keeping the structure lightweight. The engineering and attention to detail of the XR-61’s construction are not only beautiful, but fascinating. It’s like lace made from wood. The computer-designed structures are so fine that if cut and built from only wood, they might have been too sparse, but with the use of Precision Aerobatics’ FiberFusion technology—a combination of thin carbon-fiber lamination and carefully placed carbon-rod reinforcements and crossmembers—this seemingly delicate structure is not only lightweight, but rigid and strong enough to endure the abuse of 3-D hucking (freestyle flying). When the XR-61 arrived, I was anxious to check it out and happy to see that it was built just like my big airplanes—beautiful carbon-fiber landing gear bolted on from the bottom, wheel pants and cuffs just like my big airplanes, a carbon-fiber wing tube, a carbon-reinforced fiberglass cowl, and even a pull-pull rudder system with Kevlar cables. There’s a carbon-fiber battery tray and the hatch lifts off with a single pin-style latch. The wings slide onto a carbon-fiber tube and bolt to the fuselage from the inside. All of the servo mounting positions and linkages are assembled as I would do it on a bigger aircraft (but appropriately lighter). It’s a miniature version of an International Miniature Aerobatic Club (IMAC)-style airplane. The XR-61 is not a scale aircraft and my first impression was that the design seems meant to cross the boundary between precision flight and 3-D. The oversize wing and tail surfaces have a wide chord and large control surfaces for 3-D, but the long fuselage indicates the designer wanted smooth, stable lines. These two features are usually not found on one model when the intent is something such as a fun-fly 3-D aircraft or inversely, a mini aerobatic airplane. The XR-61’s scalelike look could be mistaken for a scale aircraft that has been optimized for an extreme flight envelope, but the steep canopy angle, long front deck, and stylized cowl give it a sleek, racy feeling, almost like a cross between an Extra and a 1930s-era Thompson Trophy racer. I’ve built electric-powered airplanes before and used drive systems based on advice from other modelers or recommendations from manufacturers. Precision Aerobatics’ optional integrated Performance Airframe-Drive System (iPAs) made me smile by taking out the guesswork. The company has done all of the work for you. Precision Aerobatics spent a great deal of time developing the perfect combination of motor, battery, speed control, and propeller so that you don’t have to worry. This isn’t a conservative, underpowered, off-the-shelf offering; it’s a well-designed, no-compromises package optimized to work with the airframe. The XR-61’s iPAs power package consists of a Thrust 50 outrunner motor, Quantum 70-amp programmable speed controller, a CNC-machined aluminum propeller adapter, four Hitec servos, carbon-fiber servo arm extensions, lightweight servo wire, and a Vox 15 x 8 wooden propeller. I also purchased a pair of 2,200 mAh 3S LiPo batteries, a set of vortex generators, and Precision Aerobatics’ beautiful, lightweight carbon spinner.

The XR-61 is seen here after unpacking. The picture includes the optional iPAs drive system that consists of the motor, speed controller, and more.

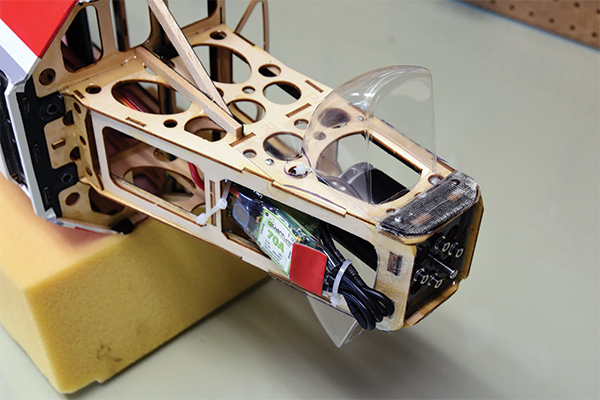

With the tough job of choosing a drive system behind me, it was time to start putting the airplane together. Precision Aerobatics includes a detailed, understandable instruction book with clear photographs and a CD with videos of construction techniques, including a short course on soldering that I found useful. Much of the construction on the XR-61 is done for you, including the well-designed pocket hinges for the ailerons. The two elevator halves are coupled with a carbon-reinforced spar and need to be installed with CA hinges. My elevator halves were not quite perfectly aligned, but they were not off enough to affect flight performance. The covering on most ARFs needs to be ironed again by the time the model arrives at your home, but the XR-61 wasn’t too bad. A quick stretch here and there was all it took. Be careful; the covering that Precision Aerobatics uses shrinks at low heat. It can pull away if you get too aggressive with the iron. Do not use a heat gun. I noticed that there are a lot of small bubbles under the covering where one color is ironed over the top of a base color. The elevator and rudder hinges are practically the only things that require CA adhesive for assembly; nearly everything else is put together with epoxy. I found that few steps went together without some custom fitting. This took more time, but it isn’t a bad thing because I have an airplane that I know is fitted perfectly. I had to file all of the servo openings to get the supplied servos in place. I opened up the area around the mounting tabs to get the aileron servos to seat properly in the wings. The horizontal stabilizers had to be cut, filed, and sanded to slide firmly into place. Additional filing and fitting resulted in perfect alignment with the wing tube. The predrilled holes in the carbon-fiber servo arm extensions all had to be custom fitted. An insert to the manual advised, “Due to the manufacturing tolerance of the CF [carbon-fiber] wing tube and sleeves, you may experience a tight fit with difficulty sliding the wing onto the wing tube.” The wing tube wasn’t close to sliding into position on my aircraft. The insert advises to sand the carbon-fiber tube; however, I chose to ream the wing and fuselage sockets using a wooden dowel wrapped with 80-grit sandpaper driven by a cordless drill. This process had to be done with great attention and finesse, removing a little at a time and rechecking it until a good fit was achieved. (Note: Precision Aerobatics now includes a wing tube that fits without modification.) The motor box fit perfectly in place. After filing the holes for the carbon rods that lock it into position, it could be epoxied in place. At this point, several steps of fiberglass and epoxy are applied to beef up the motor box. It’s not hard to do, but it would have been better had it been done at the factory to save modelers some mistakes and aggravation.

The motor box is installed and reinforced with fiberglass in the assembly process. Precision Aerobatics includes a set of cooling ducts for the motor and speed controller.

After the motor box was completed, the airplane started to come together quickly and in no time I had it ready to test-fly. Precision Aerobatics is adamant about the balance point and the company stresses that the model be precision balanced with an appropriate device rather than using your fingertips. The balance range is 3mm—roughly 1/8 inch! My balancing device has always been my fingertips, and although they aren’t accurate to within a millimeter or two, they’ve always worked well in the past. I had to wonder why an airplane that is so lightweight, with such a huge chord, has such a narrow center of gravity (CG). The model will fly fine outside of the recommended CG range, but Precision Aerobatics is demanding about how the model handles, so it is specific about the XR-61’s setup. So far, the company’s recommendations have been right on the money. I started out with throws and exponential settings that were outside of the recommended range; everybody has a personal preference on stick feel and from experience, I know how I like the pitch and roll responsiveness. Rudder adjustments are not critical and can be fine-tuned after you get pitch and roll dialed in. I placed the batteries to achieve the recommended CG (or as close as I could get with my fingertips) for the first flight. I used the recommended 50° throw for elevator, but I’m not into a lightning-fast roll rate, so I dialed it back from the recommended setting of 45° to 35° for the ailerons. For high rates, Precision Aerobatics recommends 70% exponential on both aileron and elevator. I went with 60% on the elevator, and since I was down approximately 10° from the recommended high-rate setting, I started with 50% exponential on the ailerons. For me, anything past 60% exponential tends to numb the center too much and speed up the ends of the stick beyond my control, so I generally stay away from those high exponential numbers.

Flying

The XR-61 is super lightweight. On my scale, it’s only 4 pounds, 9 ounces with the batteries installed. The maiden flight was uneventful, but it was windy, so I didn’t get much trimming in. Since that first day, I’ve been able to log quite a few more flights. The aircraft is built true and needed only a click of elevator and aileron trim. As I flew it, I kept moving the batteries forward 1/8 inch at a time. The tail tended to drop on the landing approach, and if the speed was up or there was a little headwind, it would balloon before settling in. Moving the CG forward slightly took care of this issue. The feel is that of a lightweight fun-fly type of aircraft that changes directions immediately. At any speed, it will cut a 90° corner with a square edge. Huge wings and low weight mean that the airplane carries virtually no inertia. It will start and stop rolls and turn instantly. The fuselage is thin and the airplane has a small frontal area, so when you open it up in forward flight, the XR-61 is fast. During 3-D maneuvers, I get the sensation that the XR-61 is as light as a kite. I guess that’s because the airplane doesn’t penetrate as would a heavier aircraft. It stays on the wing longer and doesn’t sink in high-alpha flight until the ground speed is almost nonexistent. This makes 3-D flight easy and controllable.

Inside of the XR-61 you can see the lightweight construction design and Precision Aerobatics’ carbon FiberFusion process that makes it strong. The company recommends a pair of 3s 2,200 mAh LiPo packs for propulsion.

With its low weight and huge wing area, the XR-61 excels in slow, docile flight, as well as high-alpha, 3-D maneuvers. The low frontal area allows the aircraft to fly fast, yet its low inertia means it will react quickly, even at high speeds.

It does rock the wings if you’re sloppy about how you enter into a Harrier maneuver, but it will stay steady if you enter cleanly. The XR-61 is different in how it does 3-D maneuvers compared with a larger airplane. Its entry or movement is forced by the big control surfaces and powerful thrust. The aircraft wants to stop when you center the sticks, while a larger airplane only has to be forced into half of the maneuver, and the second half leaves you trying to control the inertia and counter-correct to stop the model’s continued air penetration. That also means that maneuvers that usually involve inertia, such as snap rolls, flat spins, or tumbles, are brutally forced with the oversized control surfaces. When you let go of the sticks, the XR-61 stops spinning or tumbling instantly as though it reappeared from hyperspace. During the first few attempts at high-alpha rolls, I had some trouble getting the airplane to turn while rolling, but after a while, I started to really exaggerate the elevator input while the model was at the point of knife-edge flight, and that got the aircraft moving in the direction I wanted. I eventually could roll in Figure Eights without much trouble. Again, this seems to be because the airplane is so lightweight that it needs a lot of input or it wants to stay where it is. Precision Aerobatics advertises that the XR-61 needs no mixing on knife-edge flight. I was skeptical because I’ve never run across any aerobatic airplane that truly doesn’t need mixing and flies perfectly straight in knife-edge orientation. I was surprised to find that the XR-61 needs a fairly high angle of attack in knife-edge flight to keep it from sinking, even with the vortex generators, and I was even more surprised that it really does (more or less), fly knife-edge with no mixing. I use the words more or less because you do have to control the airplane during knife-edge because it tends to wander. As the rudder input increases, it tends to wander more, but at no time did I need to set up a mix with this airplane.

Optional carbon-fiber vortex generators are designed to modify the airflow over the wings and increase stability in high-alpha flight. The author flew the XR-61 with and without the vortex generators with good results.

On low rates, the XR-61 is docile and easy to fly. The airplane requires only half throttle and a short rollout to take off. With a bit of right rudder it tracks straight down the runway. After it’s airborne, you can keep the airspeed down and its character is smooth, easy flight with no surprises. Rolls require a touch of down-elevator when inverted and loops don’t spiral or start to get scary fast on the back half of the loop. Cuban 8s and Humpty Bumps are slow and controlled, and the neutral rudder input makes for a clean Hammerhead with no rollout. I found myself making frequent Hammerhead turns because they are so easy to do and look fantastic with no effort. Like any small, lightweight model, the XR-61 moves around slightly in level flight, but I found that it tracked well for its size and weight. It would take some practice for me to be able to fly a clean precision pattern with it, but if you are used to flying airplanes of this size, it will feel stable.

Add new comment