Article by Al Clark Build your own inexpensive aerobat. Read additional step-by-step instructions online and in the digital edition. Also featured in the January 2015 issue of Model Aviation.

Order Plans from AMA Plans Service

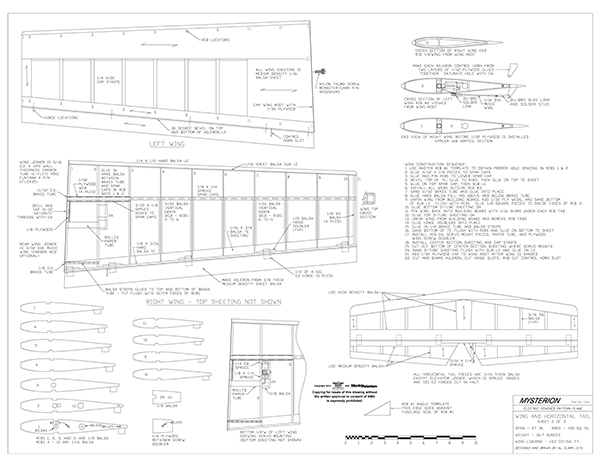

Image

Image

Construction: It is very important to pay attention to the balsa wood densities specified, especially in the tail. The Mysterion has a long tail moment and any extra weight in the tail or aft fuselage will require nose weight to be added, reducing flight performance accordingly. Study the plans to make sure you understand how all the bits go together. The fuselage is slightly more complex than the usual four-sided type, and the wings are more like glider wings than the usual powered model. All gluing is done using CA (thin) unless otherwise specified.

Tail Section

The tail is made from 3/16 balsa with a little 3/16 x 1/4 spruce (sanded down from 1/4 square spruce stock). Use medium density for the elevator and rudder and medium-hard for the stabilizer and fin. Use CA glue if you can make good-fitting joints, otherwise use Zap CA+. Draw a centerline on the front edge of the finished elevator and rudder to assist in making straight hinge slots with a #11 hobby knife, then bevel the front edges as shown on the plans. Make matching hinge slots in the stabilizer and fin. Cut some Sig EZ Hinges, or similar hinge material, in half and temporarily hinge the rudder and elevator (no glue), then round off all of the outer edges of the tail. Control horns are made from two layers of 1/32 plywood glued together with CA+. Laminate the wood, apply templates with rubber cement, drill the 1/16-inch holes, then cut the horns out and sand to final shape. Saturate the 1/16-inch holes with CA and then run the drill through them again after the CA cures. It’s also a good idea to coat the entire horn with a thin coat of CA, wipe it off, then lightly sand it smooth—this gives protection from moisture. After the horns are completed, glue them into the rudder and elevator. Then put a small scrap of balsa into the slot at the front of the horn and sand it off to match the bevel on the rudder. That avoids having a small dip in the covering at that spot. On the prototype, the fin and rudder with hinges and control horn weighed .3 ounces. The horizontal stabilizer and elevator with hinges and control horn weighed .84 ounces. If you have paid attention to your balsa density, you should be close to these weights.Fuselage

The fuselage sides should be cut from medium-density matched sheets if possible. This will ensure both sides bend the same in the forward area. Carefully cut the stabilizer and pushrod slots. It is good to use the finished stabilizer as a guide for the stabilizer slot size, ensuring a good fit. Note that the 1/16 balsa fuselage doubler pieces have two different grain directions. The forward section of the doubler is made from 3-inch wide sheets edge-glued together. Glue the forward and aft doubler pieces together, then cut out the balsa and glue in the square 1/16 plywood piece. Cut the slots for the servo rails but do not make any holes yet. Make the master rib #1 template from 1/32 plywood. Be careful to make this accurately because it locates all the holes for the wing rods and sets the angle of incidence. Glue the doublers to the inside of the left and right fuselage sides (I use CA+ but you can use whatever you are comfortable with), making sure they are spaced aft of the front edge by the thickness of the firewall F1. Now pin or tape the fuselage sides to each other with the doublers on the outside. Lay the sides down over something firm such as a piece of pine. Use the paper doubler template to properly position the master rib #1 template and pin it in place. Make holes using sharpened brass tubes in the sizes indicated. The #9 hole will have to be made using a drill bit. Cut out the lightening holes, glue on the 1/16-inch stabilizer and rudder hinge doublers, the 1/8-inch square longerons, and the vertical 1/8 x 1/4 pieces. Carefully cut slots in the stabilizer doublers to match those already in the fuselage sides. Referring to the top view, taper the stabilizer and rudder hinge doublers, and lower longerons so the fuselage sides will meet properly at the tail. Referring to the side view, taper two pieces of 1/2-inch triangular stock down to 1/8-inch triangular (use a razor plane or coarse sandpaper) and glue them to the lower edge of the fuselage doublers. Then cut nearly all the way through the triangular stock every 1/2 inch with a razor saw to later facilitate bending. Be careful not to cut into the doublers. Pin the turtledeck floor down to the building board over waxed paper and glue each fuselage side to it. (The fuselage sides are inverted for this step). Before gluing, make sure the sides are perpendicular to the building surface and tight against the sides of the turtledeck floor. Put the servo rails into their slots and then glue F3 into place with the tail end of the fuselage sides held together temporarily. Use the servos to check the servo rail spacing, then glue into place. Use a square to make sure the ends of the fuselage sides are perpendicular to the building board and glue them together. Glue F2 into position on the battery shelf using CA+. Make sure F2 is perpendicular. Dry-fit F1 and the battery floor with F2, sanding the edges, if necessary, to get a good fit. Put the battery shelf and F1 back in place, clamp or tape the sides to F1 and check the alignment over the plans top view. Check to make sure there is no twist on F1 and F2 compared with F3. Make sure there is no left or right thrust in F1. When satisfied with the alignment, glue F1, F2, and the battery shelf to the fuselage sides. If the joints at F1 are not a tight fit, go back over the joints with CA+. Sand the edges of the fuselage bottom as necessary to make sure everything is flush. Install the two lower motor standoffs now while the screws are easy to access. Edge-glue pieces of 1/16 balsa together and cut to match the fuselage bottom shape from F1 back to the center of the edge of F3. Where the ESC will be mounted, spread a thin layer of five-minute epoxy and let cure; then attach a strip of sticky-back Velcro. Now glue the 1/16-inch cross-grained bottom from F1 to the middle of the edge of F3. Sand the joints in the bottom sheeting smooth. Cut a piece of 1/32 plywood to size (grain fore and aft) and laminate it onto the 1/16 balsa bottom sheeting using CA+. Install turtledeck formers T1 through T5, made from lightweight balsa, using the angle gauge to ensure the proper angle on T1. Make sure these formers are all centered; it’s best to draw a centerline down the turtledeck floor and mark the center of each former to help guide their placement. Cut out the turtledeck sides from fairly light 1/32 balsa leaving roughly 1/16- to 3/32-inch extra all around (you can just roll the fuselage onto the sheet of balsa to see where the top of the sheeting is. It works well at T1 where there is substantial curve. Make sure the bottom edge of each side is straight. Glue the bottom edge to the fuselage side (I tack-glue it at each T former first to make sure it is tight to the formers). Dampen the upper half of the outside of the balsa sheet with water and let sit for 2 or 3 minutes, then glue the sheet to each T former starting at T5 and working forward. After you attach both sides, put a piece of 2-inch painter’s tape across the sides between all of the formers to pull the sides in. You can pull them in slightly past straight. Let them dry for an hour or two, then sand the top edges down to the tops of the T formers. Check with a straightedge as you get close. Cut out a piece of 3/16 balsa to fit the top, leave some extra width, and glue it on. Use the rear canopy former and the plans section C-C as a guide to sand the top of the turtledeck to shape. The sides will get sanded slightly as well and that is okay. If you like, you can delay shaping the turtledeck until after making and installing the pushrods so you don’t ding the top of the turtledeck while the fuselage is upside down installing the pushrods. Make up the rudder and elevator pushrods to exactly match the plans. The carbon is .125 x .065 inside diameter and the ends are 1/16-inch music wire. One inch of the music wire is scuffed well with 100-grit sandpaper and then epoxied into carbon tube. The forward end of the pushrods use Du-Bro #112 solder Kwik Links (soldered on) and the aft end uses Du-Bro #111 threaded couplers (soldered on) and Du-Bro #109 Kwik Links. The #112 solder links are a loose fit so they will need to be held straight while you are soldering them to the music wire. Install the rudder and elevator servos and cut off the servo arms so you have one arm with the holes matching the radius as shown on the plans. Make sure to use the second hole for the rudder and the first hole for the elevator when attaching the solder links. To install the pushrods, you will need to cut out a thin section of fuselage directly behind each pushrod slot, from the aft edge of the pushrod slot almost to the tail end of the fuselage. Cut this with a fresh razor blade. Install the pushrods, then carefully glue the thin sections of fuselage back into place. Cut the fuselage bottom to size from 3/32 balsa with the grain running fore and aft. Cut out the servo access/cooling hole, and CA into place. Glue the fin on making sure it is vertically aligned with the fuselage. Slide a 12-inch long 11/32 outside-diameter (OD) brass tube through the fuselage wing tube hole to check for square with the tail. If the aft end of the fuselage was perpendicular when you glued the sides together at the tail, the brass tube should be square with the vertical tail. If necessary, lower one side of the tube slightly to get it square. Check the brass tube’s alignment in the top view and check to make sure it has the same angle on each side of the fuselage. Adjust as needed. Cut a piece of 11/32 OD brass tube the correct length to match the fuselage width, scuff the ends with sandpaper, and slide it through the fuselage. Now slide the carbon wing tube through the brass tube. Check the alignment of the carbon wing tube against the vertical tail and the top view. Use balsa shims in the fuselage holes if necessary to properly position it. When everything appears correct, tack-glue the brass tube with CA+. Pull the carbon rod out and finish gluing using CA and CA+. Cut a piece of 1/8 OD brass tube the correct length to match the fuselage width at the rear wing pin position, scuff the ends with sandpaper, and slide through the fuselage. Now slide a 10- or 12-inch length of straight music wire through the brass tube. Check in the front view and in the top view to make sure the music wire is parallel to the carbon wing tube. Make any adjustments and then tack-glue the brass tube with CA+. Pull out the music wire and finish gluing with CA and CA+. Sand the ends of the brass tubes flush with the fuselage sides. Make the balsa fairing blocks at the base of the fin from lightweight balsa. Try to sand them as close to final shape as possible, then glue them onto the fuselage and fin and finish shaping them. You can put some masking tape on the fins on each side for protection while sanding. Make a center mark on the back edge of the stabilizer and slide it into the stabilizer slot on the fuselage, centering it and holding it in place at the back edge with a small T pin. Measuring from the aft stabilizer tips to a mark on the top center of F1, align the stabilizer and put a small piece of masking tape on each side of stabilizer against the fuselage to keep it in place. Use a square to make sure the stabilizer is perpendicular to the vertical tail. Adjust the slot if necessary, then glue (use CA+ if there is any gap). Temporarily install the Sig EZ Hinges into the tail section (do not glue) and add the elevator and rudder. Hook up the pushrods to the tail control horns. Make sure the servo arms are at neutral, and adjust the Kwik Links to put the elevator and rudder at neutral. Now install the pushrods guides, made from scraps of 1/8-inch hard balsa. Refer to the plans top and side views to see where the guides go. Use small pieces of printer paper as spacers on one side of the carbon pushrods when installing the guides to ensure that the balsa guides are as close as possible to the pushrods, but not in contact with the pushrods.Image

F2 has been glued to the bottom of the battery floor. The battery floor with F2 and the firewall F1 are dry-fitted and held into position with clamps at F1. After checking the fuselage to make sure it is not twisted, the battery floor and F1 are properly positioned, glue all the joints using CA. Make sure F1 has no up/down or left/right thrust before gluing.

Image

The bottom edge of the right side turtledeck sheeting has been glued to the fuselage side with CA. Next, the outside of the turtledeck sheeting will be dampened with water so the sheeting will better conform to the turtledeck formers, and the sheeting will be glued to the formers with CA.

Image

The finished cowling is taped to the fuselage and a pencil is used the mark the inside edges at the sides and bottom. The cowling is then removed and the three spruce mounting blocks are tack-glued into place with small amounts of ZAP CA+. Check the cowling for proper fit, and when satisfied, glue the three blocks using CA.

Image

After the pushrods have been connected to the tail surfaces and their length adjusted for neutral rudder and elevator, scrap balsa supports are added to the 1/8 x 1/4 hard balsa vertical stiffeners. These supports should be positioned for a slight clearance around the pushrods. These supports prevent the pushrods from bowing under high G loads.

Hatch

The hatch sides are cut from two pieces of 5/8-inch thick balsa and the top is cut from 1/8 sheet balsa. You will likely have to thin down some 3/4- or 1-inch thick balsa stock to get the 5/8-inch thickness. For accuracy, create a template of the actual fuselage side curvature using manila folder stock. Do this for both sides. Your templates should look like the ones shown on the plan for the hatch sides. Use the templates you just made to draw lines on the 5/8-inch balsa and cut out the left and right hatch sides. These will be made into triangular stock in the next step. Make the canopy former from 1/8 light plywood. The edge of the canopy former needs to be smaller than the turtledeck former T1 by the thickness of the canopy. Rest the canopy former against T1 and use a sanding block on the ends of the hatch sides to achieve a good fit between F1 and the canopy former on each side of the fuselage. Make sure the outer edges are flush with the outside of the fuselage. Now draw a line on the bottom of each hatch side that is 3/16-inch in from the outer edge (use the templates as a guide to draw this line). Remove the excess balsa on each hatch side with razor plane and sanding block so that you end up with a triangular cross-section that has a 3/16-inch wide flat area on the bottom. Refer to the hatch front view on the plans to understand what this looks like. The 3/16-inch wide flat area rests on the fuselage sides. Place the canopy former back into position centered against T1, position the two hatch sides on the fuselage so their tops are level, make sure the outer edges are flush with the fuselage outer edge, and glue them to the canopy former. Use pieces of tape on the hatch sides to position them flush with the outer fuselage edges, then glue the 1/8 balsa top onto the hatch sides. Glue F1A into the hatch with CA+. Add the 1/4-inch thick balsa piece to the inside bottom rear of the hatch. This should fit tight against the top, sides, and canopy former. Sand the bottom edge of this piece flush with the bottom of the hatch sides. Cut the 1/8 x 3/8 and 1/8 x 1/2 medium-density balsa magnet holder pieces to length. Refer to the fuselage side view and hatch views. These should fit snugly between the fuselage sides. The holes for the magnets will be made next using a sharpened 3/16 OD brass tube. Put the holes into the 3/8-inch piece first. Align the front edges of the 3/8-inch and 1/2-inch pieces and put holes through the 1/2-inch piece using the 3/8-inch piece as a drill guide. Before installing the magnets, put some Sharpie marks on them to indicate the proper orientation. You don’t want to end up having one or more pairs repelling each other! Put the magnets into the holes flush with the interfacing surface of the 3/8-inch and 1/2-inch pieces and secure with CA (balsa magnet holder pieces should be apart before gluing the magnets). Then add some CA+ to the back side of the magnets. Place the 1/2-inch magnet piece into the fuselage, with the aft 1/8 inch of it up under the bottom of turtledeck sheet, aligning it using the 3/8-inch hatch magnet piece. Check to see that the top of the 3/8-inch piece is flush with the top of the fuselage sides. You might have to slightly bevel the aft 1/8 inch of the 1/2-inch wide piece to achieve this. When satisfied, put a small amount of glue onto the sides of the 1/2-inch piece (be careful not to get any on the 3/8-inch piece); then remove the 3/8-inch piece and finish applying glue to the 1/2-inch piece. After the CA has cured, put the 3/8-inch magnet back onto the 1/2-inch magnet and make sure the top of it is flush with the top of the fuselage sides. Sand it if necessary. Glue this to the bottom of the hatch by putting some CA+ on the 3/8-inch magnet piece and setting the hatch down onto it, making sure the hatch is aligned side-to-side as you place it on the magnet. Don’t get the CA+ too near the outer edges because you don’t want to glue it to the fuselage. Center the front of the hatch on the fuselage and drill 1/16-inch holes through the F1 former into F1A. Make the two 1/16-inch music wire hatch pins and glue into F1A with CA, adding some extra CA+ on the inside of the hatch and hitting it with kicker. It’s good to scuff the gluing area of the pins with sandpaper before gluing. Plane and sand the top edges of the hatch assembly to round them off as shown in cross-section B-B on the plan.Canopy

Add small balsa fill-ins at the base of the canopy former on each side of the hatch. This will prevent there being a gap after the canopy is installed later. Cut the canopy from the SIG 11-inch bubble canopy to the shape shown on the plan; leave it a bit oversize to start with and trim and check a bit at a time until you get a good fit to the hatch. The canopy is painted on the inside with black Pactra RC car paint. Although expensive, it adheres well to the canopy which is necessary for gluing the canopy on. Cover the hatch first, and then attach the canopy to the hatch covering using a little 15 minute epoxy. That will give you enough time to clean any excess epoxy off with alcohol. After the epoxy cures, apply a 5/32-inch strip of UltraCote all around the canopy-to-hatch joint using a trim iron set on low heat. Don’t dwell on the canopy material and it will work fine.Cowling

The cowling template pieces are sized to allow the proper angles to be sanded into the edges. After the pieces are cut, refer to the cowling portion of the plans to understand how all of the pieces fit together. Because the sides all angle in at the front, there are some tricky angles on the edges. Work a little at a time and you should be able to get a good fit. Glue the four pieces together (use CA+ if the fit isn’t quite perfect), making sure they look square from the front and rear. Because of the angles on the inside of the cowling, the corners of the triangular pieces will not be 90°. They will have to be sanded to fit. Get or make some short pieces of 3/4-inch triangular stock and sand them to fit properly into the corners of the cowl. Starting at 3/4 inch will allow room for some material to be removed when fitting them into the corners. Mark each one at the proper position and taper them according to the plans. They will all be 5/8-inch size at the front. When satisfied with the fit, glue all four pieces in place. Sand the front and rear of the cowling flat, being careful not to sand off any one side more than the others. The front face should be parallel to the rear face and both should be perpendicular to the fuselage thrustline. Temporarily mount the motor, slide on the cowling (you will have to trim the triangular stock at the front of the cowling for motor clearance), slide the spinner onto the motor shaft, and check the clearance between the spinner and cowling. You want 1/16 inch all around. Sand the front of the cowling as necessary (or add some balsa if the clearance is too large) to get the proper clearance. Cut out the 1/32 plywood spinner ring slightly oversized on the outside and leave the paper template on the ring for now. You will use it to aid in alignment. Center the cowling left to right and top to bottom over F1 and tack-glue it in the middle of each side onto F1. Set the spinner ring on, add the spinner, and use the spinner to accurately locate the spinner ring. Then glue the ring to the front of the cowling and remove the spinner. File, carve, and sand the corners of the fuselage and cowling to achieve the cross-sections shown on the plans. Note that the bottom corner radius decreases as you go from the front to the back of the fuselage. Sand the aft sides of the cowling to make them fair smoothly into the fuselage sides. When sanding at the front of the cowling to the spinner ring, don’t go quite all the way. When you get close, check by putting the spinner on, then remove the spinner and do some more shaping where needed with 220-grit paper. After checking with the spinner a few times you should have a good match. Make the three spruce mounting blocks for the cowling per the plans, paying attention to the angles. Pop the cowling loose with a razor blade and touch up the spots with sandpaper where it was tack-glued. Tack-glue the three mounting blocks carefully to the inside of the cowling in their proper positions. Put a drop of CA+ on the rear of each of the three mounting blocks—not too much you don’t want to glue the cowling to the firewall—and put the cowling into position on the firewall, making sure the edges of the cowl are flush with the fuselage. After the CA+ is dry, pop the cowling loose and go back over the spruce mounting block to the firewall joints with some more CA. Reposition the cowling, make marks on the outside over the center of each mounting block, and remove the cowling. Using a sharpened 1/4 OD brass tube, make a hole through the cowling centered over each of the marks you just made. Glue a short piece of 1/4-inch dowel into each of the three holes. Carefully sand the dowel pieces flush with the inside and outside of the cowling. Reposition the cowling on the fuselage, tape it into place, and drill a 1/16-inch diameter hole through each of the dowel pieces and through the spruce mounting blocks. Remove the cowling and drill out the 1/16-inch holes on the cowling to 3/32-inch diameter. Put the cowling back on and install the three #2 button-head screws. Rub some soap onto four or five of the threads on the end of each screw before installing them and they will go in easily. If all looks good, remove the screws, pull off the cowling, and set it aside.Wing

The wings are made as two separate panels. The tabs on the ribs ensure that the panels are built with no twist. When cutting the 1/8-inch thick ribs, it’s easiest to stick two 1/8-inch sheets of balsa together with Scotch removable double-stick tape. Apply templates with rubber cement, and cut out the ribs out using a scroll saw. After cutting, sand the edges to the line with a disc sander to ensure square edges. With the templates still on ribs #1, #2, and #3, use the master rib #1 template as a guide to cut the wing-tube holes with a sharpened brass tube. This will ensure the wing-tube hole spacing in the ribs exactly matches the fuselage tube spacing. After the wing-tube holes are cut, check their spacing against the brass tubes that are already installed into the fuselage. Make the servo-mount holes and spar-cap notches in all of the 1/8-inch ribs while the two balsa sheets are still stuck together. After all the holes are made, pull the balsa pieces apart from the double-stick tape, peel off the paper templates, rub off the rubber cement, and draw lines across the tabs so you’ll have a sanding guide when you remove the tabs. Glue 3/32 x 1/8 spruce pieces to the aft edge of the spar caps from the root end to the outer edge of rib #3 using CA+. You can make 3/32 spruce by just sanding down some 1/8 square stock. What follows is for one panel. If your building board is large enough you can build both panels simultaneously. Pin the lower spar cap in place over the plans—don’t pin through the cap—and glue all of the ribs to it. Make sure to use the rib #1 angle template from plans sheet 3 on rib #1. The other ribs should be perpendicular to the building board. Lay a straightedge along the top of all the ribs at the aft ends. If there are any gaps, put some paper shims under the rib tabs to bring any low ribs up to level. Bevel the top edge of the 1/8 hard balsa trailing edge (TE) to match the angle shown in the wing cross-section views. Then glue the TE to the ribs making sure the top edge is flush with the top of the ribs. Glue on the top TE sheet. Install the top spar cap, making sure that the 3/32 x 1/8 piece you added earlier is on the aft side between ribs #1 and #3. Bevel the top of the 1/16 sub LE to match the angle shown in the wing cross-section views, then glue it to the front of the ribs making sure the top edge is flush with the top of the ribs. Install all of the spar webs outside of rib #3, making sure the grain is vertical. Cut a piece of 11/32 OD brass tube to fit, scuff the outside with sandpaper, and glue it to ribs #1 through #3. Install the hard balsa fill-ins above and below the brass tube using CA+. Remove the wing panel from the building board. Add the 1/32 plywood webs between ribs #1 and #3. Sand the bottom edge of the sub LE to the proper angle flush with the edges of the ribs (protect the ribs with masking tape while sanding). Glue the 1/8 square balsa pieces to inside edges of rib #11 on the top and bottom. Glue the bottom 1/16 D-tube sheet on. The sheet only goes back to the center of the bottom spar cap, not the aft edge. Put the wing back onto the building board with scrap 1/16 balsa shims under each rib tab. Pin the ribs at each tab and use pin clamps or something similar to hold the wing down along the lower spar cap. Cut and fit the top 1/16 D-tube sheet so there is roughly 1/16 inch of overhang at the sub LE, and make sure it is straight along the spar. Again, the sheet only goes back to the center of the top spar cap, not the aft edge. Mark the center of the top spar cap at each end. Now glue on the top D-tube sheet using the following process. Apply aliphatic resin glue (Titebond, Sig Bond, or other) along the top of ribs #2 through #10 between the sub LE and spar cap. Align the top D-tube sheet on the spar using the center marks and CA all along the spar cap. Now, beginning at rib #6, pull the D-tube sheet down over the front of rib #6 and tack it to the sub LE at rib #6 with some CA. Continue to do this at each rib, alternating sides (rib #5 and #7, rib #4 and #8, etc.). When you have tack-glued the D-tube sheet at every rib, apply CA to the sheet all along the edge of rib #1 and rib #11. Remove the wing panel from the building board and finish gluing the D-tube sheet all along the sub LE. Carefully cut off all rib tabs and sand if necessary to get down to the line you previously drew at each rib tab. Glue the five 1/8 balsa hinge doublers into place. Cut the rear brass tube to length and glue a small plug of scrap 1/16 balsa into the outer end. Scuff the tube with sandpaper, and glue to ribs #1 and #2. Sand the bottom of the TE to the proper angle flush with the bottom of the ribs (protect the ribs with masking tape) and glue on the lower TE sheet. Fit and glue in some scrap balsa strips above and below the rear brass tube. Glue the 1/4 square spruce and 1/8 x 1/4 spruce servo mounts, and rib #2A into place. Glue in the plywood wing screw doubler with CA+ and glue in the rolled paper tube (made from a couple layers of printer paper or something similar). Sheet the top and bottom of the wing from rib #1 to #3. Note the sheeting overhangs rib #3 by 1/16 inch. Remember to cut out the bottom sheeting to allow the aileron servo mounting access. Add all of the cap strips to the ribs and the sheeting from rib #10 to #11 on the top and bottom. Sand the D-tube sheeting flush with the sub LE and glue on the hard 1/4 x 1/2 LE piece. Sand the LE and wingtips to shape. Sand the wing root so everything is flush. At this point you can use the carbon wing tube and music wire rear pin and slide the wing onto the fuselage to check the fit of the wing root. Remove the wing and make any corrections with a sanding block. Cut out the 1/32 plywood wing root cap slightly oversize. Cut the four holes into the cap referring to the plans and using the master rib #1 template. Glue the cap onto the wing root, then carefully sand the edges flush with the wing sheeting. Make the ailerons from medium-density 3/8 balsa. You only need to remove balsa from one side to get the final shape. Use a razor plane to shave one side close and finish with a sanding block. Square the TE (in the end view of the aileron) with the sanding block. Draw a centerline down the front of the aileron and cut the hinge slots with a #11 hobby knife. Bevel the front of the aileron per the wing cross-section shown on the plans. Locate and cut the slot for the aileron horn, ensuring that the slot will allow the horn to be perpendicular to the aileron. Make the aileron horn in the same manner as was done for the tail section, and glue the horn into the aileron. Tap the wing-screw hole in the wing root with a 10-32 tap, saturate the threads with CA, let cure, and re-tap. Cut the aileron hinge slots into the wing TE with a #11 hobby knife. Check the fit of the aileron by dry-fitting all of the hinges, and sand the outer end to fair into the wing tip. Repeat for the other wing panel.Image

Finished right wing panel has the servo installed and the aileron hinges dry-fitted. The 1/32 plywood root cap can be seen. The aileron control horn is laminated from two layers of 1/32 plywood.

Image

The right wing panel is completed except for the LE and plywood root cap. The small hole behind the wing spar tube will be tapped for a 10-32 nylon screw.

Image

Tapping the wing hold-on screw hole with a 10-32 tap. After tapping, the threads are saturated with CA to harden the balsa. The LE has been added and beveled, ready to be rounded off to the proper shape.

Image

Ailerons are made from 3/8 balsa. Draw a reference line on the TE side so you achieve the correct TE thickness, then use a razor plane to bevel the balsa. It is only necessary to plane one side. Finish with a sanding block to get a smooth surface. Next draw a centerline on the front of each aileron to use as a reference when beveling the front edges and making the hinge slots.

Finishing

Check the entire airframe and touch up any areas that need it with 220-grit sandpaper. Then go over everything with 400-grit paper. Vacuum and use a tack rag, and you are ready for covering. I prefer UltraCote because it tends to wrinkle less over time. When you cover the wings, leave the servo pocket uncovered, then come back with a separate piece of covering, made to fit over the opening, that has a hole in it for the servo shaft. After covering, attach the ailerons, elevator, and rudder using CA on the Sig EZ hinges. Remember to attach the elevator before the rudder! I like to use small pieces of .015-thick vinyl as spacers to ensure even gaps everywhere before hitting the hinges with CA. Be sure to clean up any excess CA immediately. Install the motor and ESC. Do not install the spinner and propeller yet! The motor wires go through the elongated slot on F1. The ESC is dropped through the slot on the battery shelf and stuck to the Velcro you previously installed. You will need to add an extension to the ESC receiver wire to reach the receiver. Route the power lead and receiver leads up through the appropriate holes in the battery shelf. Install the aileron servos, routing the servo leads through the paper tubes and out the wing roots. Cut the servo arms to match the wing plans sheet. Make up the aileron pushrods as shown. Center the servo arms and attach the pushrods. Plug the rudder and elevator servo leads into the receiver, and plug in two short extension cables for the left and right aileron. Plug the ESC extension lead into the receiver. Mount the receiver and its satellite using Velcro at the positions shown on the plans. It helps to first apply a thin coating of five-minute epoxy where the Velcro goes. Let the epoxy cure and then stick the Velcro down. Set the 3S 2,700 mAh LiPo battery in place on the battery floor (my battery was nearly all the way forward). Cut two pieces of Velcro strap to size and install them around the battery using the slots in the battery floor. Cut a piece of Velcro to go around the aft end of the battery (this strap is at 90° to the aft strap and attaches to it above and beneath the battery shelf) to prevent it from sliding aft. Plug the battery connector into the ESC power connector, bind the receiver, and set up your radio programming to the throws and exponential settings noted on the plans. Check the motor direction and swap the motor leads to correct it if required. Turn off the radio and disconnect the battery from the ESC power lead. Now install the spinner and folding propeller. Move the battery pack fore or aft as required to balance the center of gravity (CG). The prototype balanced with no nose weight required. Add some nose weight if needed to achieve the CG shown on the plans. After the CG is achieved, glue a small piece of EPP foam or balsa on the battery floor between F1 and the front of the battery to prevent the battery from sliding forward against F1A. Check the lateral balance by resting the aft end of the fuselage on a hard surface and supporting the front by holding onto the spinner. If needed, add some lead to a wingtip by removing a small piece of covering material and balsa from the bottom wingtip sheeting and glue in a small piece of lead, then replace the balsa and covering pieceBalsa and Build List

Visit www.ModelAviation.com/balsa to learn more about balsa grades, grains, and density. You can also downloadDocument

Image

Document

Document

Image

Image

Comments

Looks Great

Looks Great

Plans

Where can I find these plans?

in the magazine and this page

Mysterion

Why can't I look over the Mysterion plan?? I have looked all over the AMA web site and can't seem to find it. How much does it cost?? Again, I can't find the answer anywhere.

Craig

AMA 70942

order plans

Plans

Hello,

I would love to try and build one of these planes. Are there plans for it?

Thank you,

Kyle

form above

Very good

Very good

Mysterion

Ordered Plans Today Looking forward to the Build (and flying) when I get the current build off the board

Ordered Plans, No Verification

Hi Greg... I ordered two sets of the Mysterion on Dec 21/22, 2014. The ordered went through PayPal & they notified the money was sent to AMA (some $42.xx). I was expecting that I would get confirmation & estimated delivery from AMA. So far no emails & I haven't been able to get status at the AMA website. I'm very excited about building this plane - looks to be a fabulous design. Can you ease my mind a bit & confirm that the order went through OK? Thanks. Al

Hi Al-

Mysterion plans are shipping

Al, Your plans order shipped today. We were swamped with orders and are slowly getting caught up after the holidays.

Plans for MYSTERION.

plans

New AMA plans site.

Looking forward with great expectation to the new plans site.

Done right, this can be a big advance for AMA.

Best,

Peter Gregory

AMA 1047551

Mysterion Plans

Thanks for your reply to my comments regarding AMA's policy on providing a plan for this airplane.

While I can certainly understand the position the AMA has taken, it still doesn't provide a plan for this design in the magazine itself....period....

If the AMA truly wants to continue to provide services to the membership, please reconsider your current stand on printing plans.

Yes, some members will order plans, not having seen them in the magazine, as evidenced by some of the comments that preceded mine. However, there may also be an equal number out there who, like me, want to see the plans first, and who will, now, NOT order plans for the same reason I didn't.

Either way, you will STILL loose a percentage of the probable revenue.....either through members just refusing to order a plan, "Sight-Unseen" (like me), or, through those members who will copy the plan illegally.

There is no "best" answer to this situation.

All I know is that, as a long time model-builder, I have seen a number of really GREAT magazines go by the wayside.....'R/C Modeler'.....'Model Builder'.......and now, 'Flying Models'. ALL these great publications offered their readership an opportunity to build 'unique' models, from scratch.

I miss that, but then, I'm an "Older" member ( since the 1950s). And, as this "Older" member knows all too well, times are changing.

I'm truly saddened to see my organization changing in this way.

I encourage you to reconsider your position on this issue, and begin by giving the membership back something it always had.....and we now miss..........the REAL plan in the magazine.

Sincerely,

Duie Matenkosky

AMA # 18574

Hi Duie-

Mysterion

Similar to Duie Matenkosky, I have been scratch building since the late 1960's. These days it is cheaper to buy as opposed to build. In addition, it is rare that a design catches my eye enough to motivate me to build. The Mysterion is a design that I would like to build but when I consider the price of plans $24 +$6 shipping, the airplane falls outside of the advertised "inexpensive" category. It is unfortunate that the scratch builder is being squeezed out of the hobby because of cost, especially when you consider that modelers such as myself have played a significant role in developing this hobby.

Because of the cost, I am one of those builders who would "illegally" copy the plans, or more likely, cut and build the aircraft from the smaller plans that used to be printed in the magazine. I would argue that the number of people who "illegally" copy plans is absolutely insignificant with respect to your revenue in any case. In all my years of modelling I have yet to come across a source for illegally copied plans.

It would be nice if you would provide a digital copy of the plans, possible as a pdf so that the builder might have the option of tiling and printing from a desktop printer, or paying a blueprint service to print full size sheets. Of course, the option to have the AMA plans service print and mail plans could be an option as well. At least this would give a modeler on a budget some options to consider. I would gladly pay $6 for a downloadable file, and the AMA plans service may just make more money.

Thank you for your time.

Mark McCormack

AMA164430

future site

Cost of plans

This is undoubtedly a superb design.

Should I be able to finish mine as well as the author's - some fine work there.

However, the price of plans makes me balk - especially not being able to peruse them first.

Best,

Peter Gregory

AMA 1047551

Balsa Wood Density

Hello,

I have never built a balsa wood plane other that the smaller ones that come with pre stampeded balsa sheets in the box. I now this is probably a huge step ahead of my airplane building skills but I am up for the challenge. I have a questions though.

It is stressed in these plans to use the proper densities/hardness of balsa for the build so the balance and CG is correct. Can I get some help with understanding how to differentiate the densities of the balsa I am buying? or at least a good source for balsa that give a selection of balsa along with density/harness listed in the description that are comparable to the ones required in these planes. I have looked around and cannot find anywhere that provides this level of specification and therefore wonder if it is even possible to find. I am almost left to believe this is something a seasoned builder determines by experience with selecting from personal stock.

If this isn't that important how is a plane such as this usually balanced after the build so that I do not need to be concerned as much with the density/harness. Could there be structural concern during flight if the wrong harness is used for instance on the wing leading edge?

Thank you,

Kyle

Kyle,

Kyle,

You have a couple different options. Probably the best option is a good hobby shop that has a balsa wood selection that you can choose the appropriate weight balsa for the wing fuse and wing.

National Balsa , Sig and Balsa USA all have good balsa. What I do is buy more balsa than I need and use a gram scale to put the weight where it needs to go.

Scratch building is a rewarding experience. With each project you will learn more and soon will be doing projects you will be proud of.

Mysterion

Hi Is there a place to get answers regarding the plans and building process for the Mysterion. For example: Where exactly are the fuselage longerons shown on the plans?

Thanks

Bill

Bill,

Bill,

The fuse longerons are shown on the fuse sheet, section c-c in the lower corners. and the length information is printed below the rudder.

I see that now. Thanks

I see that now. Thanks Bill

Cost of plans

The Mysterion looks like a great plane, would love to build one. But the cost of plans for this, like all AMA plans kills my interest. I have built many planes when the plans are available full size and I tile them. The Coyotee is the latest, nice plane, good plans, cheap build. With the current cost of materials and covering added to your price for plans it just eliminates your models as possibilities. I would gladly pay $5.00 to download a good PDF full size set of plans for tiling, but your prices are just too much. I am one of a fast dwindling line of builders. Soon your plans will just be archives in a museum. None of the new flyers will be builders. Too bad.

George

George,

George,

I am afraid you are not comparing apples to apples. The Mysterion is printed on 3 large sheets requiring 90 pages for tiling. The Coyote is a park flyer. One small sheet excellent for tiling.

Laser kit

There is a laser kit for the Mysterion on the East coast available by calling Marcs laser shop at (802) 453-3610

Plan image in magazine

Regarding no full plan image in the magazine,...

I'm with Duie, above. I sad it then (but not here) and I'll say it again. Sad there was not a plan image in the magazine. I too must study a plan fully before I'll buy it. Disturbing that you assume enough guys are stealing the plans, by going through all the trouble to enlarge a magazine image. Those people are not modelers they are thieves. I've drawn plans for industry. It is a very tough and demanding task. A lot of time and thought is invested. They just do not magically appear in a magazine so people can have free access to them. So nobody tell me people who enlarge plans from the magazine (or anywhere) without paying for them first aren't thieves. Buy the plan! It's what helps keep the hobby what it is today,... or maybe what it was. Now,... back to the magazine. Yes, you are doing an injustice to members who still build, by not providing a full image of the plan somewhere to study. I see that you NOW have decided to published the plans, not necessarily in the magazine, but in this digital construction article. Thank you for that. But I wonder, isn't that making it easier for >thieves< to steal the image for enlargement by utilizing the even better image provided above? I assume you have added the plan because of many complaints from >builders< in this hobby. Please don't punish us builders by not publishing the plan.

plans return

Mysterion Build

Has anyone started a build on this plane yet, or a build thread on one of the RC web sites.

I have stared a build and have ran across a problem with the F3 install(possible incorrect size). Any answers would be appreciated.

[email protected]

Misterion Build

I found an error in the turtle deck floor end, which the plans show it ending at a point, where it should have 1/4" width as it sits on top of both 1/8" fuse sides.

Mysterion

The cost of the plans doesn't bother me, as my club members and I have built 3 planes from them but the $130 for the specified servos and the cost of the other parts and materials eliminates this design from the "inexpensive aerobat" category. That being said, the plane does build into a very nice performer that I am impressed with.

Add new comment