By Dave Chesney | Photos by Bill Shumway

As seen in the May 1981 issue of Model Aviation.

THIS MONTH: a helicopter that looks like it might have been designed for a Space: 1999 or Star Trek TV show. Doug Law of Baldwinsville, NY lets us in on his impressions of the Horizon Helicopter. The photographs of Doug's Horizon are the work of Bill Shumay. Here is Doug's letter,

Dear Dave:

I thought you and )'our readers might be interested in some information on the Horizon Helicopter. As many of your readers may know this machine was designed by Hubert Bitner and Helmut Holder in Texas. The kit has been anticipated for a couple of years and it is my impression that it is now in production.

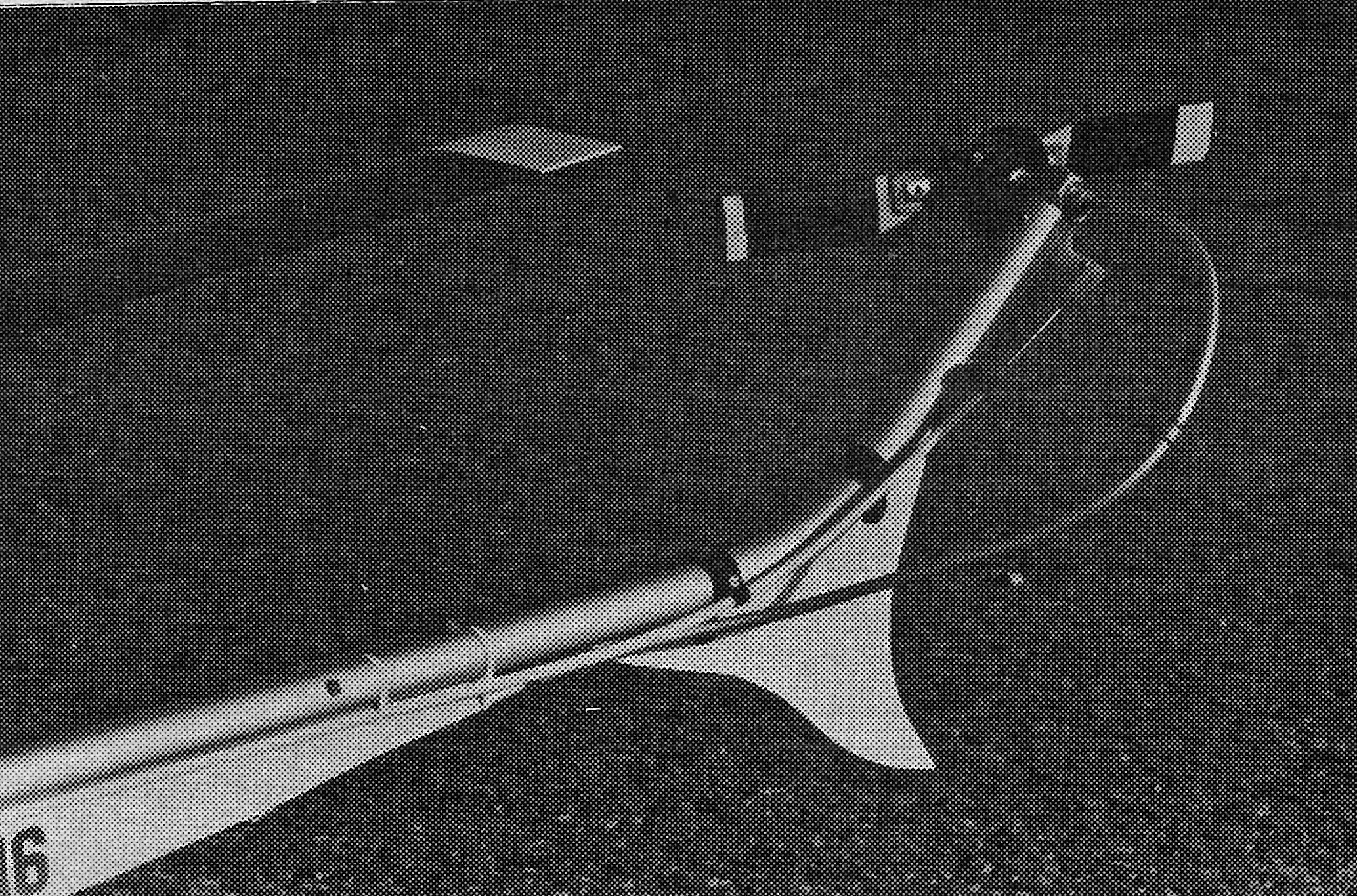

This is the Horizon helicopter built and flown by Doug Law, Baldwinsville, NY. picture reveals classy, futuristic lines of this new machine. See the thing which looks like a thin extension of the left landing skid? It is a plastic tube housing the radio antenna! Blunt end on the fuselage pod is actually the open end of the cooling fan shroud. The dark-looking protuberance below the tail boom, near the tailskid, is the aft end of the tuned pipe muffler. The engine shroud adds to the illusion of a full fuselage and scale-like appearance.

I was very impressed with the Horizon at the 1980 Nationals, and purchased the kit shortly thereafter from Horizon Model Crafts, 3625 E. Lookwood, Houston, TX 77026.

The lit is of exceptional quality. Most metal parts arc clear anodized (I think that is the process), giving a soft satin finish to the aluminum. Having heard of radio problems because of the insulating quality of anodizing, I checked the completed machine with an ohmmeter and found that all parts, no matter how remotely located, were all electrically connected. The machinery and parts were of excellent quality, and they all fitted where and how they were supposed to.

One nice thing is that all parts, including the hardware. arc standard American sizes. The instructions include sections on construction, setup, preflight checking, and problem solving. In fact, even a "what to check for after a mishap" is included. For a .60-sized collective-pitch machine, the Horizon is amazingly simple. Several clever construction and setup procedures are employed, including a pitch gauge that made me say "I wish I thought o.f that!' Total time spent in construction and setup was about 20 hours.

Although the Horizon is a "frame and tube" machine, the inclusion of side cowling, a pleasing, front body, a sub-fin, and main fin make the machine stand out as very stylish and even a bit futuristic looking.

The photo above shows the right side of the Horizon with the shroud removed. That’s an HB .61 helicopter engine for power (note the stock, heat-sink cylinder head). Stub “prop” is the cooling fan. Note toothed-belt drive, tuned pipe installation, and mini-spinner for direct-starter engagement.

The Horizon is a flybarless machine with a main rotor diameter of 53 in., operating at approximately 1.575 rpm. The main blades require approximately one-and-a-half ounces of weight in each tip to compensate for the lack of a flybar. These weights go into a slot milled into the back side of the hardwood leading edge. When the balsa trailing edge is in place, the weights are entirely enclosed. Properly installed, this method insures that there is no chance of the weights coming out. The tail rotor blades are made of wood rather than plastic, probably to provide a lower inertia force.

All ball bearing used in the Horizon are double shielded. Thrust bearings as well as double ball bearings are used in the blade holders.

The engine mounts horizontally, facing rearwards, and is connected to the clutch through a drive belt. A three-blade fan is used to pull air through the side cowling for engine cooling. This method of cooling has proven to be very effective. The fuel tank is mounted in the cowling opposite the engine, and is located on the center of gravity, as well as on the center of the carburetor.

The tail rotor is driven by a speedometer-type cable in such a way as to not require any gears. This eliminates considerable friction, as well as parts. With this system, it is not necessary to disengage the tail rotor system for autorotations.

Tail rotor, with control linkage and speedometer-cable drive. Flexible drive eliminates the usual gearing and allows a graceful upsweep in the boom—keeps the tail rotor out of the grass and allows graceful, Hollywood-style landing flare.

Photo above reveals spacious provision for the RC installation. The three servos on the upper tray control main rotor cyclic and tail rotor pitch. The white servo lower down moves the tray to provide collective pitch and tail rotor mix. The fifth servo is to the throttle.

Collective control is produced by a sliding swashplate, which is held at four points. The linkages go to both sides of the cyclic servos, producing a very firm swashplate with a minimum of feedback to the servos. Only two linkages are required from the swashplate to the head for direct blade control. The head itself is extremely simple, rugged, and easy to set up. Heavy plastic is used for the side cowling and front body. The canopy is Lexan, and the sub-fin and fin are made of balsa and plywood. The front body is designed to break away on impact for minimum damage—it works!

Photo above depicts the flybarless rigid rotor head. Simple and sturdy! Swashplate attaches to cyclic linkage at four points—minimizes slop.

I used an HB .61 PDP helicopter engine with tuned pipe in my Horizon. This engine runs well, is easy to adjust, and provides excellent power. I am not sure if the pipe actually adds much, but it is neat-looking, and gets rid of most of the oil. The radio equipment includes a World Engines seven-channel receiver with EMS 1511H servos. I use an Ace Silver Seven transmitter which I have modified for concurrent use of both exponential and mixing (throttle and T/R), as well as external reversing and two functions on the throttle stick for inverted flight. My machine weighs 11 pounds ready to fly, without fuel. This could probably be reduced to about 10 pounds without the tuned pipe, as considerable nose weight is required when the pipe is used.

When it came time to fly my Horizon, I was a bit apprehensive. I have been flying Helicopters for only a year, and I had heard mixed stories about flybarless machines. Having learned on and only flown a Heliboy, I was also concerned about how the Horizon would compare in performance. How sweet it is! After only minor trim adjustments, the Horizon lifted into a very steady hover. One thing I was immediately impressed with was the complete lack of vibration. Cyclic control inputs responded immediately, giving a very solid feeling. Tail rotor control was very positive in both directions, and the tail rotor mix was very close to being correct. The collective response made me wonder if this machine really weighs 11 pounds. It was now time for some flying, so a little forward stick and away she went. An engine flameout at 25 feet proved the durability of this machine. After rearranging the skids, I fired up the engine and put in several more flights.

One noticeable difference between a flybarless machine and a good flybar machine, like the Heliboy, is an accentuated upward pitching in forward flight. It took me a number of flights to become accustomed to—and compensate for—this characteristic.

The Horizon is capable of very precise flying, as well as having full aerobatic capabilities. The control setup is very easy, and can be anywhere from “mild to wild.”

In the last few weeks, I have modified my Horizon for inverted flight. Yes, and while it is inverted, I have my hands full, but I have managed several extended periods of inverted flights. I need to work out a couple of minor details and then practice, practice, practice.

To sum up my opinion of the Horizon, I would say that the combination of simplicity, durability, styling, and precision of control makes it well suited for the flier who desires quality and performance. I thoroughly enjoy my Horizon and feel that it will take a prominent position in the Helicopter community. If anyone is thinking about a high-performance collective machine, I certainly recommend that he investigate the Horizon

Sincerely, Doug Law

As Doug says, the Horizon has been around for several years. The machine and pilot/co-designer Hubert Bitner have shared an impressive record of wins wince I first saw it at the Lake Charles Nats (1st place Expert that year). You may recall my comments about the Horizon from that Nats coverage.

From what I have seen, I would say that this machine will make an excellent addition to the flight line. It is rugged, attractive (downright beautiful), and has been thoroughly tested by its designers and others. I look forward to seeing more Horizons on the horizon!

Comments

Add new comment