RC Soaring

ONE OF THE MOST common repairs on a modern sailplane is a broken tailboom. This month’s column is a real treat. We’ll learn how Dennis Harvey, an absolute genius in composite sailplane repairs, does it.

I have the dubious reputation of being a wizard at carbon-fiber repair. I say dubious because that also means I’ve made countless repairs—I have crashed so many times during the spot-landing learning curve. I’ve had decades of experience with composites throughout my career and also with my boating hobby. I share here the tricks to make a broken fuselage tailboom repair virtually invisible.

This first part that is included in the print magazine concludes with the model being ready to fly with an internal sleeve installed, but cosmetically, the fuselage still shows its wound. The second part is here and focuses on making the damaged area nearly invisible and creating a significantly stronger repair.

The repair is on an F3B Pitbull, where the tailboom was broken clean in half. The pushrods were removed later and replaced because of delamination. The Pitbull has a particularly thick tailboom layup, but the techniques in this article also apply to the thinner layups of F3J and F5J fuselages.

Sleeving the Break Area

In Photo 1, the first thing you’ll notice about the sleeve (which will be installed inside of the broken fuselage) is that both ends have a six-point crown shape. The purpose of this is to transition the tailboom stiffness so that you’re not breaking the tailboom again at the edge of the sleeve on the next hard landing. This is highly likely without this transitional shape. The shape is easy to cut with a Dremel tool and a diamond cutting wheel.Image

Please note that the uncrowned length of the sleeve should be approximately 20mm greater on each side of the break. The crown points should be roughly 30mm. Use these measurements and your break to determine how long your sleeve should be in the next step.

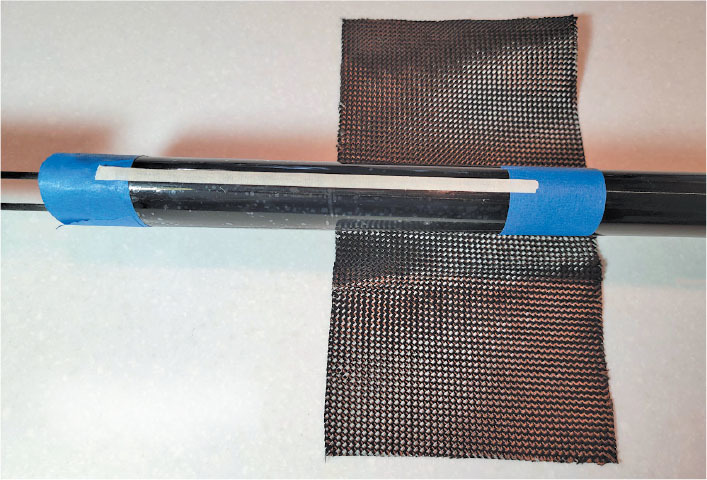

Molding Your Sleeve

In Photo 2, the first thing you must do is determine the dimensions of the carbon-fiber cloth that you will use to mold the sleeve. The parameters for determining the length of the sleeve were given in the last section. In the Pitbull example, the sleeve needed to be 110mm, so considering molded-edge scrap, the carbon-fiber cloth is 130mm wide. I recommend that the piece of carbon-fiber cloth be biased-ply—the fiber is oriented 45° to the edges. All fuselages are molded this way because the orientation results in a strength and stiffness that is approximately 40% greater than if the strands were oriented along the axis and circumference of the tailboom. What is the other dimension of the cloth? You will mold the sleeve on the outside of the tailboom aft of the break so that it will eventually slide into the larger section of the fuselage where the break occurred. Choose the place on the fuselage where you are going to mold the sleeve and carefully tape over the area with clear packaging tape. Epoxy will not adhere to this tape, so you will not need a release agent. Make sure that the tape overlaps so that no fuselage is exposed. I taped approximately 200mm of length and used 1.5-inch wide masking tape to protect the edges of my workspace. Next, measure the circumference of the fuselage where you will be molding. You must determine how many layers you need for the sleeve. I use calipers to measure the thickness of the fuselage at the break and compare it with the thickness of the carbon-fiber cloth. In this example, I need three layers of 5.7-ounce/square-yard carbon-fiber cloth, which worked out to a swatch that was 320mm in length. The last thing to notice in Photo 2 is the thin strip of lighter-colored masking tape on the top of the work area. After the raw sleeve was completely cured, I used a Dremel tool with a diamond wheel cutter and carefully cut the part along the top until the lighter-colored tape was just visible. Pry the part apart and remove it. Next, use the Dremel with the diamond wheel to cut the sleeve to the crown shape shown in Photo 1. I exclusively use West System 105 Epoxy Resin with 206 Slow Hardener slow-cure catalyst.Installing the Sleeve

As shown in Photo 3, after the sleeve is cut to shape, fit it into the forward section of the fuselage. You might have to grind down the inside of the seam where the fuselage halves join. You could also have to use the diamond wheel to increase the size of the sleeve cut line so that it fits snugly into the forward section of the fuselage. Fit the sleeve so that half of the uncrowned section length is concealed and half remains ready for the tail section. Make sure that it is aligned by using a straightedge along the fuselage. Set this aside and let it hard cure.Image

Final Alignment and Sleeve Bonding

In Photo 4, after the epoxy was slathered on the sleeve and inserted into the tail of the fuselage, an aluminum splint was used to ensure that there was no offset in the tailboom surfaces and to ensure alignment in the pitch axis. The yaw-axis alignment was done by visually sighting along the fuselage seams. The roll axis is tricky. You might have to twist the fuselage sections fore and aft to ensure that the tail is aligned with the wing.Image

Composite RC Gliders

Ready to Fly Optional Newsletter subscription: www.bit.ly/3p9i5wi +49152 31700200 compositercgliders composite_rc_gliders @compositercgliders [email protected] www.composite-rc-gliders.comNext Step

If the sleeve was the same thickness as the broken fuselage section that you repaired, you can fly the airplane at this point. However, I recommend that you continue to part two of this article to enhance the strength of the repair and dazzle your friends with how you made the repair invisible.Preparing the Tailboom for a Splice

The tailboom now has a sleeve bonded to the inside that can support the loads. By splicing the tailboom material on either side of the break, the repair is almost doubled in strength and will allow for a resilient finish. Photo 5 shows how the tailboom material is ground to a concave shape in anticipation of adding layers of carbon fiber and epoxy. Look closely on the left side of the remaining carbon fiber on the tailboom to see the concave shape. You should grind this down until the sleeve is visible and the break has been ground away. How wide should the concave area be? You usually want to set your masking tape guide 15mm past the break. With the Pitbull example, the break fluctuated approximately 20mm, so the span of the concave area was 50mm. Do not worry about making the raw carbon-fiber area pretty. Leave the surface rough to ensure good adhesion.Image

Molding the Splice

Put fresh masking tape on either side of the concave area and make sure that it is only one layer thick. Photo 6 shows the carbon fiber just covering the edge of the masking tape. You have to decide how many layers of carbon fiber are necessary. If you use the same weave of carbon-fiber cloth as you did for the tailboom, it should be the same number of wraps. It is better to err on the side of too many carbon-fiber layers than not enough because you will be sanding them down. You don’t want to have to fill in any valleys. With the Pitbull, I changed from using 5.7-ounce/square-yard cloth to a finer 3.75- ounce/square-yard cloth, so instead ofthree layers, I needed four. When you apply this carbon-fiber/epoxy mix, make sure that you work out any air pockets or voids to make the rest of the job go easier.

Image

Roughing the Surface Shape

After the carbon fiber is hard-cured, use a Dremel sanding disk and/or a coarse sanding block to take the carbon fiber to the thickness of the masking tape perimeter. You will know you are there when the black carbon fiber disappears from on top of the masking tape, but the masking tape is still intact. Photo 7 shows the splice rough-shaped to within the thickness of the masking tape on the perimeter. The masking tape has been removed, so you’re ready for the next step.Image

Fine-Sanding and Ready for Gel or Clear Coating

Photo 8 shows the splice area blocksanded to the final shape. Using a sanding block helps to make sure that you have worked out any waviness. You can ding the surrounding area and not worry because there is still a sleeve under your work. For the best results, I try to do the final sanding with 1,200-grit wet/dry sandpaper.Image

Final Finish Coat

For the Pitbull, the fuselage was coated with black gel. I chose to apply a few coats of epoxy with black pigment that was specifically formulated for epoxy. The final coat (it took three) made the repaired area look flawless. Photo 9 shows the finished repair that has been buffed out with automotive polishing compound. My finger is exactly over the point at which the break had occurred. Notice that the reflection of light on the surface shows that there is no waviness or surface distortion in the repair. For a clear epoxy fuselage that shows off the carbon-fiber structure underneath (no gel coat), using regular epoxy for the final coat can give you stunning results. For the last coat, after preparing the surface with 1,200-grit sandpaper, I lightly smeared epoxy over the work area and wiped nearly all of it off, except for a light film that was too shallow to have brush marks. This usually produces a glossy finish. It’s critical that the epoxy and catalyst are mixed to ensure curing. No post-processing is necessary, although you could buff it out. There you have it. Try this yourself, and when you are finished, show off your masterful repair to your flying friends.Image

A huge thank-you to Dennis for taking the time to teach us all how to do a perfect repair. A future column will feature a professional wing repair. Don’t forget to purchase tickets in the huge F3J raffle for the USA World Championship team that is scheduled to compete in Slovakia. The last chance to enter the drawing is the end of August 2022. Until next time, go downwind and soar.

Image

SOURCES:

League of Silent Flight (LSF)

www.silentflight.org

Team USA F3J

www.teamusaf3j.com

West System

(866) 937-8797

www.westsystem.com

Comments

Add new comment