Written by Fred Randall staff

As featured on page 54 in the November 2011 issue.

Read an abridged summary from the article.

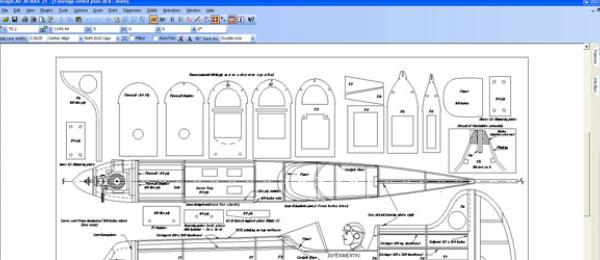

I decided to start designing my own as I had done so many years ago as a child. I had worked in a technical trade before retirement and was reasonably computer literate. After making several sketches of my proposed airplane, I looked for a CAD program that would make the design work easier and more enjoyable.

I was familiar with AutoCAD, but I couldn’t justify the cost of such a program for designing model airplanes. A Google search unearthed a program called ModelCAD 3000 from Upperspace Software. The price was reasonable, so I ordered it along with a companion program: Wingmaster.

It took me some time to get the hang of using the programs but it was well worth it. The programs were downloadable and there was a 275-page PDF user’s manual. I occasionally referred to it, but my main sources of instructions were the program help files.

My pencil sketches were of a 1930s-style racer, one of my favorite types of aircraft. I am a product of that generation, so perhaps my preference is natural.

Slowly I transferred my rough sketches to computer files. I didn’t like the looks of constant chord wings, but the thought of having to scroll saw a group of different size ribs led me to a design that utilized contoured balsa ailerons to provide a more pleasing outline to an otherwise rectangular wing planform (my CAD-designed plan became the Golden Era 60).

I had seen laser-cut parts used on ARFs and wished that I could find a way to have my parts cut for me. I delight in assembling a model aircraft, but fabricating a multitude of balsa and plywood parts is not as enjoyable.

It was by chance that I mentioned this wish to Joe Candela, the proprietor of Creative Hobbies. Joe had answered my many questions about RC flying during a dozen or so visits to his establishment—before I had bought anything at all! I had approached people in several other hobby shops with my questions, but most were reluctant to take time for me unless I was a paying customer, so when it came time to finally buy airplanes and equipment, Joe got my business.

Joe responded to my casual comment by saying, “Bring in your patterns; we’ve got a 100-watt Epilog Radius laser engraver out back.”

I was stunned! I immediately began learning how this unfamiliar device worked. A laser cutter or engraver is simply a computer printer that etches or cuts material using information downloaded from the computer, rather than printing it out on paper.

Because I installed the ModelCAD program in the control computer, I could use the program files for cutting; however there is a more mainstream way to do it.

ModelCAD, as do all CAD programs of which I am aware, generates vector graphic files. The difference between raster and vector graphics was well covered in “Designing in CAD,” David Walker’s excellent introduction to CAD in the August 2011 issue of MA.

Before you become unhinged at the thought of having to purchase a pricey program such as AutoCAD or CorelDRAW in order to produce your laser-cut patterns, there are alternatives. The key is that the program must be capable of exporting .dxf or .dwg files.

You do not need a program capable of 3-D rendering. Usually, programs with this capability cost more, and the learning curve is steeper. The simpler programs are easier to use than the more complex ones, which was why I gravitated to ModelCAD. Perhaps it was a mistake because it created non .dxf vector graphic files. I was fortunate to have access to a laser cutter that I could experiment with and develop a workaround solution to getting my parts cut.

In order get your parts cut; you must design “cutting patterns.” You need to know the size of the laser bed and the size of available materials from which to cut your parts. You must then provide cutting patterns that best utilize the size of material that you plan to use.

Read the entire article including specific programs and exporting techniques on page 54 of the November 2011 issue.

Read how to design in CAD on page 31 of the August 2011 issue.

Image

Comments

Thank you

Thank you

Told to make contact

I had a former customer contact me and tell me that at one time you may of been looking for a company to cut your kits. I was in the Hobby business for over 30 years and very aware of the mechanics involved. I have been a manufacture for over 38 years and I do outside work on occasion. Currently I own 3 laser cutters, 2- 50" X 50", 1- 4' X 8' If you are interested in having some kits cut and provide me DXF files IO can do so at affordable prices. I can draw if necessary, however it is better that I am provided quality ready to cut files. I can be reached M-F 10:00-5:30 Est. Thank you, Tony Castronovo President, Warehouse Hobbies Inc.

Ziroli P51D Mustang

Hi Tony,I'm looking for somebody to do parts for me.I live in Ontario,Canada and I can only find companies in the US.They are quite expensive with the exchange and I'm on a fixed income,any suggestions?

Scale up die cut

Hi, I'm looking at building a Top Flite Corsair and Spitfire both gold edition 60 size. I manage to get the full scale plans but the ribs and bulkhead are not drawn on the plans. They are shown in the manual more or less as pictures. I tried to have then scale at a printing show but the full scale cannot be reproduce as the picture are not to scale. Do you know how to get thos die-cut patterns scale to proper size from the manual or do you have those die-cuts in your portfolio of plans and templates. Let me know. Thanks. Marc.

It is a comment

It is a comment

Topflite Corsair parts

I bought a kit on Marketplace and it's missing a few parts.Do you know anyone who would reproduce these?

Citation 60

Kun je aan een cad tekening komen van de citation spanwijdte 66 inch van Yoshioka uit 1981? Waar de patronen van alle snij onderdelen van balsa en multiplex op staan?

Add new comment