Written by Lawrence Klingberg

A simple solution for Giant Scale models

As seen in the October 2011 issue of Model Aviation

MANY YEARS AGO, as a scratch builder of large airplanes, I was limited by the size of model I could build by wheel sizes available from the hobby store. Unhappy with that limitation, I decided to make my own wheels for my ¼-, 1/3-, and ½-scale airplanes. The question was how to make them and from what.

While shopping at a local swap meet, I found the perfect source for large airplane wheels. Kids’ small bicycle wheels come in 8-inch to 10-inch sizes. Another plus is that the bicycles’ plastic fenders can even be used on some of the airplanes, specifically the Fokker C.II and most of the trimotors of the 1930s. A photo of one of the little bicycles used is shown in the article.

The wheels weigh roughly ¾-pound. Made from plastic, they can be painted in dull black or white if the aircraft uses that color of wheel.

To begin construction of a set of wheels, locate a bicycle with the size wheel you need and make sure it is similar in appearance to the one shown in the photo. They usually have a 15/8-inch diameter hub. Remove them from the bike frame, inspect them for any excessive wear or cracks in the plastic, and check to see if the tread is in good condition. They are generally in good shape because kids are not hard on these bikes.

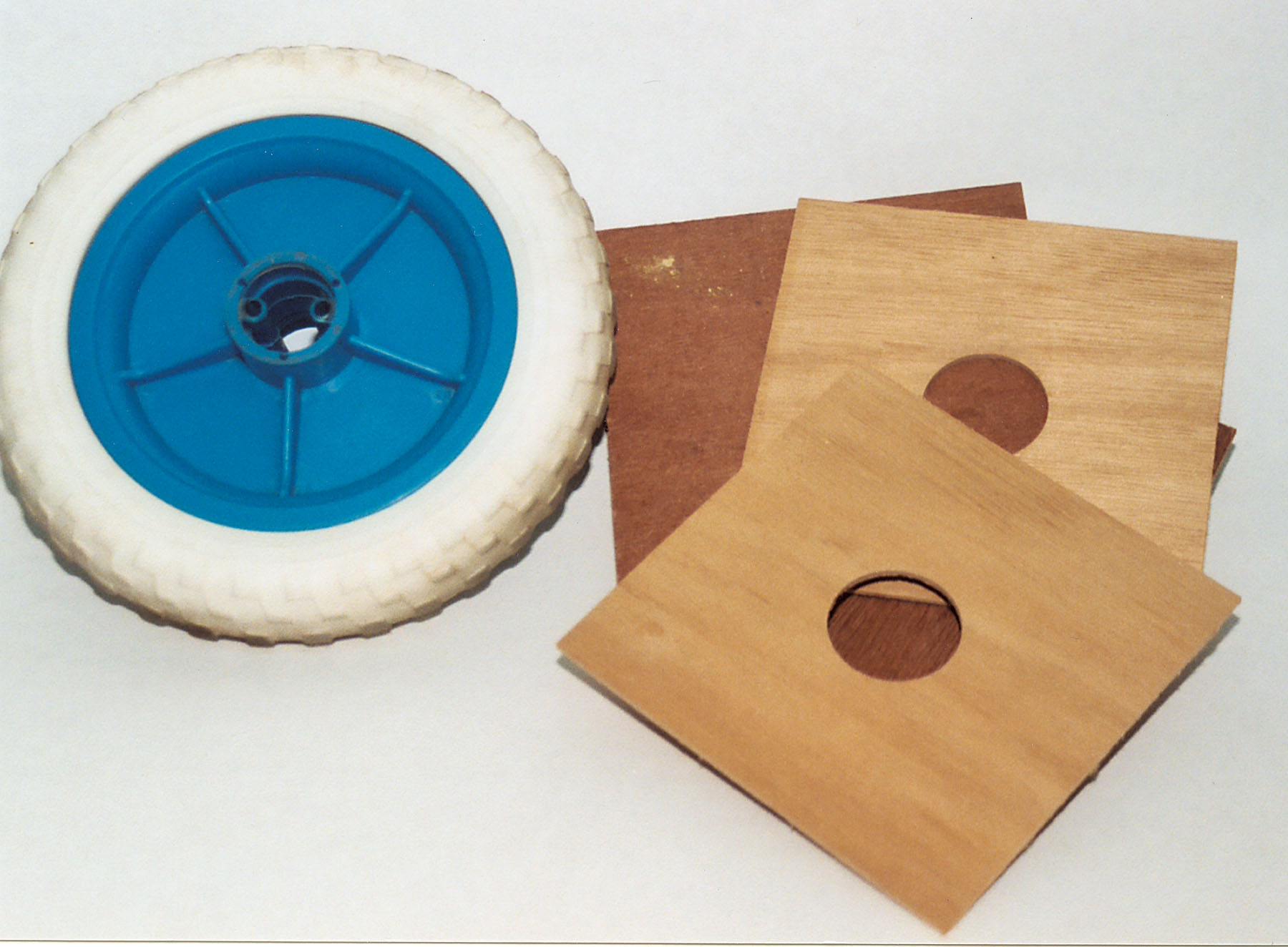

When satisfied that the wheels are in good shape, cut four pieces of 1/8-inch lauan plywood slightly larger than the outside wheel diameter to make two wheels. Cut out the inner hub hole to 15/8 inches.

Make a 15/8-inch spindle as shown in the photo and cut the outer diameter to approximately 6 inches or whatever your size wheel measures. You should now have four discs that you can place onto the wheels for size and make any necessary adjustments.

When the wheel discs are finished, the next step is to make four inner-hub discs. These are needed to create a 1/4-inch axel hole in the wheel center. Cut them from 1/8-inch lauan plywood on a band saw using a ¼-inch spindle as a guide. Also make four hub discs out of ¼-inch balsa using the same ¼-inch spindle as a guide.

Now it’s time to start assembling a wheel. Make a template from heavy cardboard, lay out 16 spoke lines on it, and cut out 1/8-inch boxes. After making the template, mark off the four large discs. Place a marked-off disc on the wheel, glue the small, inner disc pieces together (lauan plywood onto a ¼-inch balsa disc). Do all four of them.

Accurately position a small disc in the center of the hub. The wheel will not run true if it is not precisely positioned. The lauan plywood piece disc will be on the inside and the balsa on the outside.

Below: The author chose this type of bicycle to construct his scale wheels. The bike wheels range in size from 8 to 10 inches.

These 1/8-inch lauan plywood blanks are used to make the wheel discs.

Use a band saw to cut an outer circle from the 1/8-inch lauan plywood to make the wheel discs.

A wheel disc is placed on the wheel topped with the 15/8-inch hub used on the jig for cutting the outer diameter of the disc.

Cut some 1/8-inch pine pieces so that they form spokes when glued onto the large discs. They should look like the ones shown in the article. Depending on the size of your wheels, they will be roughly 2 inches long and taper from the inside hub to zero inches on the outside of the rim. Glue 16 of these pieces onto the wheel disc using 5-minute epoxy. When they are dry, take the wheel disc off the wheel and put 5-minute epoxy up against the hub to form a glue fillet against the inner disc. This strengthens the wheel for hard landings. Creating the other three discs should go quickly now that the procedure is perfected. The next step is to cut two pieces of ¼-inch balsa and place in between two “spokes.” Create a ½-inch hole that you will later use as an air valve stem hole. Make sure that the four wheel discs are smooth and fit the wheels properly then coat them with three or four coats of Balsarite, using the fabric-type covering in a green can. Having done that, proceed to cover the discs with Solartex. Cut 16 pieces and iron on. When ready to add additional pieces, coat the overlap part with more Balsarite—roughly ½ inch on each seam—and finish covering the rest of the disc. Coat the center of the disc and iron on a 2-inch piece of Solartex to cover the center portion. Finish the other three wheel discs in the same manner. To complete the discs, go to a craft store or fabric shop and buy dressmaker’s hooks and eyes. You will need approximately 250 pieces. Only the hook part will be used. Glue them on with thick CA glue, spaced at roughly ¾-inch intervals, as illustrated in the picture. To accomplish this job, make a board with a spindle hub and raised with a wedge of wood. This will elevate the disc so that the hook eyes will not slide off until the glue has set. This job is rather tedious and I highly recommend using tweezers. When all of the hook eyes are glued onto the discs and set, clean out the 1/2-inch valve stem hole and drill a 1/16-inch hole for a short piece of toothpick to be glued in as a filler stem. This will be painted silver in the final detailing. It is now time to decide what color to paint the wheel discs. I use silver Rust-Oleum spray paint from Home Depot, but any good-quality paint will do. The plastic tires of the wheels will also need to be painted. I use flat black on some tires and leave other tires white because some old airplanes had white tires. After painting the discs, I finish the job by running heavy black cord around through the hook eyes and zigzag it back and forth gluing it at both ends. The only thing left to do now is to assemble the wheels and get them ready to put on a ¼-inch axel. I use wheel collars to hold them on, along with one washer on each side of the wheel. The wheels are roughly 2½ inches wide and they weigh approximately 1½ pounds. The finished wheel is pictured on a ¼-inch scale Bellanca WB-2. I have used these wheels on my airplanes—even on my ½-scale Farman Moustique—and have experienced no problems with them. If you find you need large wheels on the airplane you are building, don’t hesitate to construct a pair. This method will satisfy anyone. Happy landings and keep ’em flying.

Solartex is applied to the under-construction disc on the left. It sits next to a nearly completed version. You can also see the filer hole for the valve stem.

A typical “spoke” shape made from 1/8-inch pine. Two wheels require 64 pieces spokes.

A board is used to glue the hooks at ¾-inch intervals around the wheel disc. The wedge of wood under the disc makes an incline so the hooks remain level. Use thick CA and tweezers for this work.

This finished set of scale wheels is installed on a ¼-scale Bellanca WB-2. They give the landing gear a scale touch.

Sources: Balsa USA (800) 225-7287 http://shop.balsausa.com Rust-Oleum (877) 385-8155 www.rustoleum.com Written by Lawrence E. Klingberg 8111 Dartmoor Dr. Huntington Beach CA 92646

Comments

Add new comment