Written by Tony Stillman

Understanding and utilizing basic features of your RC transmitter

Technical Bonus digital content in the July 2017 issue of Model Aviation.

Bonus video

Today’s model fliers have many great choices for radio equipment. Most are multi-model capable, allowing a single transmitter to control multiple aircraft by creating a program profile of each specific model, and then saving it to the radio’s memory to be recalled whenever you want to fly that aircraft again.

This article will try to help new modelers better understand the features available in most RC transmitters today. Knowing how the features affect the model’s flying characteristics can transform a hard-to-fly model into an easy flying, enjoyable aircraft. Let’s get started!

Transmitter Features:

Mode Types

It is important to understand how the transmitter is set up. The stick mode (Mode 1 or Mode 2) refers to the stick configuration of an aircraft transmitter’s control sticks. Mode 2 is the USA standard and has the elevator/aileron on the right stick and the rudder/throttle on the left. It is most likely what you are using.Servo Reversing

This feature allows you to reverse a specific channel’s servo rotation. If the servo on a specific channel moves in the opposite of its intended direction, this feature corrects the problem.Sub-Trim

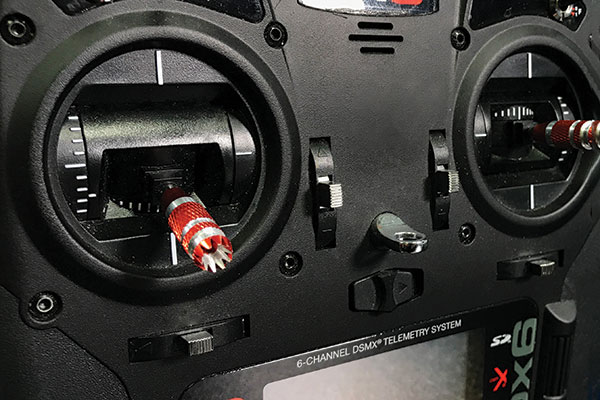

Sub-trim allows you to fine-tune the neutral position of the servo arm on a particular channel.Image

End-Point Adjustment

Also called adjustable travel volume (ATV) in some systems, this allows you to preset the maximum travel of a servo on either side from its neutral position, or the high or low side of a throttle channel. This allows you to make changes to match the throw settings that are recommended for the aircraft. Dual Rates A dual-rate switch on the transmitter can reduce the amount of servo travel. The aileron and elevator control channels are the most common channels used with this feature, although some radios will also have a rudder dual-rate switch. Select low rates, and an overresponsive model can be made easier to control. Exponential This feature adjusts how linear the relationship is between the transmitter stick and the response of the servo. This is normally used to reduce the servo response near the neutral or center of the stick, and increase it as the stick is moved toward the maximum travel. The effect on the model is to give it lots of control movement (like a 3-D model) and still fly like a trainer.Mixing

Two control channels can be mixed or coupled together so that they move together when only one control channel is activated. Many scale models require a combination of aileron and rudder to turn. Mixing does this electronically at the transmitter.Failsafe

This feature automatically returns a servo or servos to a neutral or a preset position in case of a malfunction or interference.Programming a Model

Now, let’s now go into more detail on each of these features to better understand them. I put these features in this specific order because this is the order you should use them in setting up a new model.Get your transmitter and your airplane fuselage with all of the radio gear installed, in front of yourself and follow along using your radio and airplane instruction manuals.

This exercise will help you see the results of the features one by one, and how they can make your model flying a more enjoyable experience.

We want to program this aircraft from the beginning. Referring to your radio manual, access the model menu and select a new model, or reset the programming of the model you want to use. Name the model and then turn off the receiver and transmitter.

Now that all of that is saved to memory, turn everything back on. Because we have the wing off of the model to view the servos, we will only focus on the elevator, rudder, and throttle channels on this particular airplane.

Image

Elevator

First, verify that the servo you want to be controlling the elevator is following the motion of the elevator stick on your transmitter. If the elevator is working when the rudder stick is moved, for example, you need to swap the connection of that servo to the correct channel. Check each function to make sure you have this correct for all servos. If you find something wrong, swap the servo connectors to the correct channel of the receiver until all of them respond properly.Next, we need to see if the servos are moving in the correct direction as we move the sticks. Connect the elevator pushrod to the servo arm. If you find that the elevator servo is moving in the wrong direction when you pull back on the elevator stick, then you can simply move the pushrod to connect to the other side of the servo arm or wheel.

If you don’t have space or can’t move the pushrod, then the elevator channel needs to be reversed. Check with your manual, access the servo reversing program, and then select the elevator channel. Change the setting from normal to reverse to change the direction. Now your servo should be moving in the opposite direction when you pull back on the stick, resulting in up-elevator motion. Simple and easy!

Check the rest of the channels and make changes as needed in the servo-reversing program so that everything is moving in the correct direction. If you have an electric-powered model, you will need to follow the instructions for the ESC to verify that the throttle stick direction is correct. Make sure that you do this with the propeller removed from the motor!

Sub-Trim

Now that we have all of the controls working in the proper direction, let’s move to the next step: sub-trim. Make sure that all of the sticks and trims are in the neutral position. You can verify the trims using the display and listening for the tone change when the trim is centered.With that task completed, take a close look at the relationship of the servo arm and the pushrod attached to it. For 99% of all setups, you want the pushrod to connect to the servo arm and create a 90° angle. You can unscrew the servo arm screw, pull off the arm, and reposition it to get it as close as possible. This ensures that the servo’s motion will have the same effect (deflection angle) on the control surface as you go from one side of neutral to the other.

In the case of elevator control, if you move the stick 1 inch to either side of neutral, you should get the same angle change on the control surface. This will make the aircraft responsiveness symmetrical throughout total travel. This basic starting point is required to get the most out of future adjustments.

If you find that the servo arm is not perfectly at 90° to the servo and pushrod, then you need to go into your sub-trim menu and adjust the channel. You will find that this is a very fine adjustment, and you can be extremely accurate.

Go through the rest of the controls to make sure they are the same. In the case of glow or gas-powered models, make sure the carburetor arm is also at 90° to the pushrod when at neutral stick or half throttle. You might even need to make an adjustment to the carburetor arm position to achieve this. Check with your engine instructions for how to do this.

Now that the servos are working in the proper direction and fine-tuned to exact center, we want to adjust the total travel of the servo to get the correct amount of travel at the flight controls.

Review the travel amounts that are listed in the instructions that came with the aircraft. If you don’t have instructions, then you have to use your best guess, or ask another modeler who has the same or a similar airplane, for recommendations on control surface throw.

After you decide on the amount, it’s time to do some measuring. There are several tools out there that you can purchase to check control throw and they all have advantages, but for now, we are going to use an old-fashioned method: a ruler. Let’s use the elevator surface for our example.

With the radio turned on and everything centered, check the elevator position to be sure it is exactly neutral. If not, adjust the clevis in or out until it is in neutral. Get your ruler and align the elevator’s trailing edge on an inch or millimeter mark so you can measure how far the control will move with stick movement. Move the elevator stick on the transmitter to full up-elevator and measure how far the control surface moved. Check this against the recommended throws.

If the travel is too much, try moving the pushrod connection to the next hole outward on the control horn on the elevator. You can also move the pushrod connection at the servo horn in toward the center of the servo arm. Either one or both of these adjustments can be done to get close to the desired amount of throw.

To increase the throw, move the pushrod connection in the opposite direction. You want to be roughly the same distance from the center of the servo to the pushrod as you are from the hinge line of the elevator to the pushrod connection. By trying different positions, you will find a location that gives you nearly the desired travel on the elevator.

Image

Endpoint Adjustment

Now that you are close, you can use the endpoint adjustment feature to adjust the travel to the exact specifications. Most radios will typically default to 100% travel in both the up and down side of each channel, which can be individually adjusted. You might think that this is maximum available travel, but most are adjustable up to 125% and some even up to 150%. This allows you to increase above 100% to get the travel properly adjusted.Keep in mind that you want to keep the endpoint adjustment between 75% and 120% in order to have the best resolution for the servos. If you need more or less throw than these numbers, go back and change the pushrod connection point on the servo arm or control horn as needed, and repeat the process.

Following the radio instructions, access the endpoint adjustment program and select the elevator channel. Move the transmitter stick to give full up-elevator and measure the travel. If you need more travel, increase the percentage. If you need less, decrease it.

Do this for both the up and down side of the elevator, and once it is completed, recheck it. When you are happy with the setting, move to the rudder and throttle. For glow or gas engines, you want the full-throttle setting to fully open the carburetor, but not stall the servo.

Listen for a buzzing sound from the servo that would indicate that you have gone past the stop for the carburetor and the servo is no longer moving. Reduce the travel until the buzzing stops and make sure the carburetor barrel is fully open at full throttle.

For low throttle or idle, you want to move the stick to low throttle and completely close off the opening in the throttle barrel using the sub-trim. Now open it back up to show approximately 1/16 inch of opening. This should be a starting point for idle that can be finely adjusted using the trim lever next to the stick when you run the engine. For electric motors, follow the instructions on the ESC to set the throttle travel.

Let’s review. We have the servos moving in the correct direction and have centered the servos and adjusted the travel to get the recommend travel on all controls. We are ready to fly, right?

Well, maybe not. There are a few more features that you need to be aware of that can help make the model easier and more fun to fly.

Dual Rates

Let’s discuss dual rates. This program allows a pilot to adjust the total travel of a specific control surface with the flip of a switch. A good example of this is on the elevator. Most aircraft instructions will come with travel recommendations for both high and low rates. Previously we set up the high-rate travel. Now, you can adjust low rates.Referring to the radio manual, select the dual-rate program and choose elevator. Find the switch that controls the elevator dual rates. When the switch is flipped up toward the top or back of the transmitter (depending if it is mounted to the front or top of the transmitter), that is usually the high-rate position. You won’t need to make any adjustment for this switch position.

Now flip the switch down or back toward yourself. That will be the low-rate position. Referring to the radio manual, reduce the 100% setting to roughly 70%, or whatever measurement for the control travel at low rates. Adjust the percentage until you achieve the desired amount of travel.

Now, if you hold full up on the elevator stick and flip the switch back and forth, you will see the travel of the elevator change. This allows you to select more or less throw while flying in order to complete a specific maneuver. In the case of elevator, it usually takes more elevator to perform snap rolls or spins that you would want to use in normal flight, so you take off and land and do most of your flying at low rates.

When you want to perform a spin or snap, flip the switch and you have the control you need to do the maneuver. Afterward, switch back to continue flying. Very handy indeed! Go through the rest of the channels and set them up as well. Dual-rate rudder can be helpful to keep you from oversteering on takeoff by switching to low rates when you start the takeoff roll.

Exponential

Exponential is something that I think most newcomers don’t understand. Exponential changes the response of the servo from linear (proportionally following the exact motion of the stick), to a nonlinear response.Taking elevator and aileron control as examples, most aircraft are sensitive around the neutral point, so only a small amount of control movement is needed to make minor corrections in flight. This is where typical use of exponential comes in. Adding some exponential to the control will make the servo move less when the stick is moved around the neutral point and more when the stick is moved near the end of its travel.

Depending upon the radio system and how it is set up, you can select exponential as part of the dual rate program, so that you can have different amounts of exponential with different amounts of travel as selected by the dual-rate switch position. Again using elevator as the example, enter the radio program for exponential and select elevator. By flipping the dual-rate elevator switch, you can determine where you need to make the change in the exponential program.

At high rates, you will normally want a higher amount of exponential—40% to 70%. Check your manual for recommended amounts. At low-rate elevator, you will normally set a lower amount, maybe 20% to 50%. With these values entered, slowly move the elevator stick from neutral to full up.

You will notice that the control surface moves very little around neutral, but then moves much farther as you get to full stick deflection. Again, do the same for all of the other controls. Sometimes exponential can help with glow and gas engines, because most have almost no power increase from 70% to full throttle. Adding exponential will give a more linear engine response to your throttle stick.

In some instances, you might find that your setting actually results in making the travel around neutral greater and the travel at the end smaller. In this case, you will need to go the reverse direction (negative number) on your exponential input. That is, instead of 40%, make it -40% on the screen. This information is usually in your radio manual, so check that before you start making changes.

Using exponential on ailerons and elevator are a must for me! It makes all of my models—from trainers to jets to 3-D machines—easy to fly. I can fly lazily around, or switch to high rates and high exponential to hover or perform 3-D maneuvers. With many of my models, I don’t even use dual rates, only exponential. Then I don’t have to flip switches or remember to flip them when I am flying!

Mixing

Finally, I’ll touch on mixing. Most fliers will not get into mixing at all, but some will find it makes certain models easier to fly. Take a J-3 Cub, for instance. Most will turn better using both rudder and ailerons to bank. The full-scale J-3 Cub definitely requires rudder to turn properly!Using a mix to allow a small amount of rudder to automatically move whenever you use the ailerons can make flying easier, especially for inexperienced pilots. Simply follow the programming instructions and select aileron as the master channel and rudder as the slave.

Set the mix to 10% or whatever is recommended in the aircraft manual. Make sure that the rudder is moving to the right when you are giving right aileron input! If it is backward, simply reduce the number until it reads -10%.

There is normally a switch that turns this mix on and off, so you can steer normally on the ground, but switch the mix on in flight. In crosswind landings, sometimes it is important to be able to turn the mix off to compensate for wind.

I hope this brief introduction into basic radio programming helps you better understand your radio and how its features can enhance you model flying experience and even aid in quickly setting up a new model! See you at the field! —Tony Stillman

[email protected]

Comments

Radio Programming Basics article.

This is a terrific article and a great help for the new-comer to the hobby. I just returned a survey you sent me and suggested that these types of articles be included in the magazine and then compiled into a pamphlet that all new AMA members could get as part of your member services or you could charge a small fee for it. I was taught how to fly be was not taught so many of the bacis such as those discussed in this article and it would have been a great help to have such info. It may well be out there but it is not well publicized. Remember in many cases a newby doesn't know what he doesn't know and often doesn't know where to look for the info. I suggest a tab on the web site, or reminders in the videos you send and reminders in the magazine aimed only at the newby...maybe even a chat room where a dummy like me could go to get a quick answer to a lingering question, remember, not everyone is willing to show their lack of knowledge by asking one of the guys at the field a question.

Transmitter Programming

That's a great article I wish I had that information when I got started flying. Instruction books with radios don't define terms as related to setting up the transmitter.

Tony,

Tony,

Great article for beginners and others! I wish I could have found a similar article when I began flying. I relied on other fliers at the field but they often don't express exactly what and how things are being programmed. If you expand this article you might include setting up safety kill switches for both fueled and electric power.

Anthony

Xmitter programing.

Xmitter programing.

Todays new radios

Wayyyyy to complicated for the average pilot !!!

AMA article on rc radio

AMA article on rc radio controls/programming

Transmitter Explanation

Tony,

I appreciated your article. I have been RC flying for a year with the assistance of club members.

Your article put all the advice in an informative perspective.

Now on to improved flying.

Radio Programmng Article

This is an extremely WELL written article. This is for the beginner as well as the experienced!

Much needed information!

Kudos to Tony!!

Programming video

This is a well presented video on beginning to program an aircraft receiver. It is no substitute for the manual, but compliments it well. Thanks!

Radio Programming Basics

Great article for learning the basics of modern RC transmitter programming!

After I had already laid out 400 bucks for my first "computer" radio-control system many years ago, I found I had invested in a non-intuitive transmitter programming protocol that forced me into being subservient to the system, instead of me being in charge.

Fortunately, a fellow RC flyer invited me to borrow his different brand transmitter and program my airplane for flight with his transmitter. What a difference!! The sequence, control labeling, menu callouts, all seemed to match how I learned standard aircraft terminology and how priorities of operation just flowed from my brain into the transmitter and on to the model airplane.

I subsequently scrapped my new transmitter, licked my wounds, and bought the same brand and model my friend demonstrated. Great decision- I love all the RC gear of this brand and it keeps me happy in my great hobby. Had I taken a few hours time at my local flying field to find the RC system that matched my brain, I would have had that 4oo bucks to buy more airplanes!

The take away? Before you buy, make sure you will own your RC system, not the other way round.

Frank Horine

Radio Programming Basics article

Have a Sig Senior with flaperons. How do I program. I already chose the flaperons option, but I donot know where to go from there.

Add new comment